Acepack Full Servo Packaging Machine: Revolutionizing Modern Packaging Solutions

Mar 12, 2025

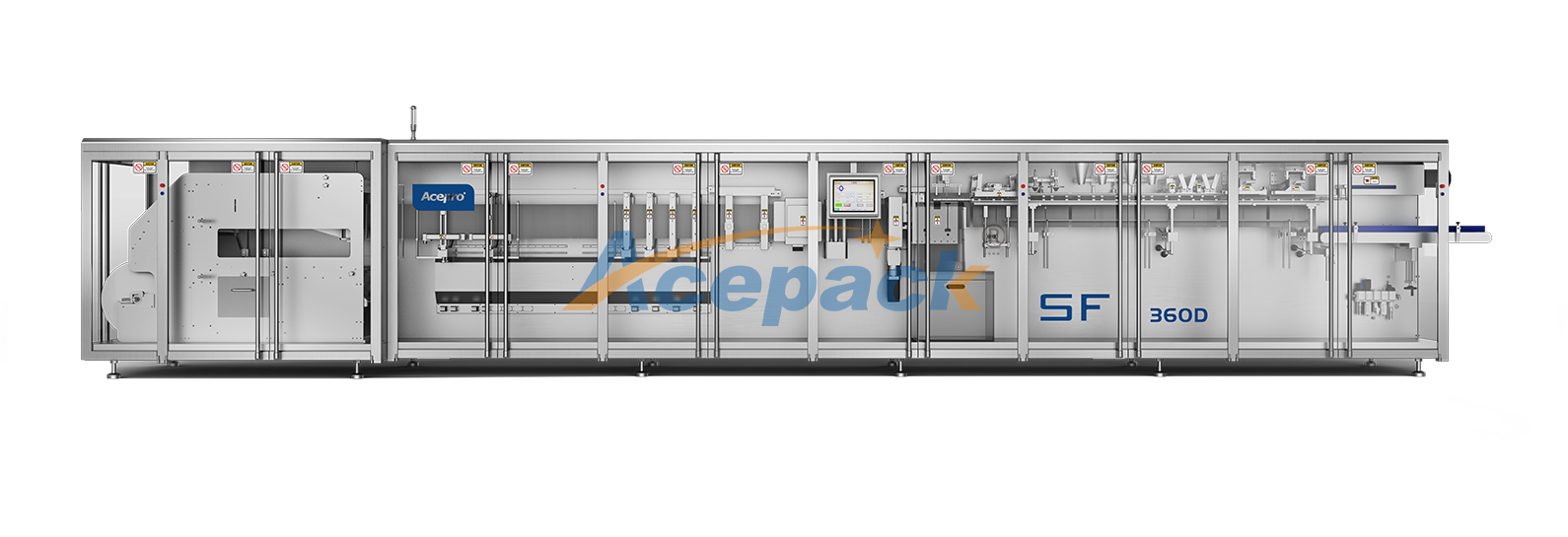

In today’s fast-paced industrial landscape, packaging plays a pivotal role in ensuring product quality, safety, and market appeal. As industries strive for greater efficiency and precision, the demand for advanced packaging machinery has grown exponentially. The Acepack Full Servo Packaging Machine stands at the forefront of this evolution, offering a cutting-edge solution that combines high performance, flexibility, and reliability. Designed to meet the diverse needs of industries such as food, pharmaceuticals, and chemicals, this machine is redefining the standards of automated packaging.

1. Overview of the Acepack Full Servo Packaging Machine

The Acepack Full Servo Packaging Machine is a state-of-the-art automated packaging system powered by a fully integrated servo control mechanism. Unlike traditional packaging machines that rely on mechanical drives, this equipment uses advanced servo motors to precisely control every stage of the packaging process, including material feeding, bag formation, product filling, sealing, and coding. This innovative design ensures unparalleled accuracy, speed, and adaptability, making it suitable for a wide range of packaging applications.

2. Key Features

-

Unmatched Precision

The full servo control system is the heart of the Acepack machine, enabling precise control over every movement. This ensures consistent packaging quality, minimizes material waste, and reduces the risk of errors, even when handling delicate or irregularly shaped products. -

Exceptional Efficiency

With its high-speed operation and seamless automation, the Acepack machine significantly boosts production output. It is capable of handling large volumes with minimal downtime, making it ideal for high-demand manufacturing environments. -

Superior Stability

Built with premium materials and engineered for durability, the Acepack machine delivers reliable performance even under continuous operation. Its robust design reduces maintenance requirements and extends the equipment’s lifespan. -

Versatile and Adaptable

The machine supports a wide variety of packaging formats, including pouches, bags, and sachets, and can easily switch between different product sizes and shapes. This flexibility makes it a valuable asset for businesses with diverse packaging needs. -

User-Friendly Interface

Equipped with an intuitive touchscreen control panel, the Acepack machine simplifies operation and monitoring. Users can easily adjust settings, track performance metrics, and troubleshoot issues in real time, ensuring smooth and efficient production.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor