How Can Food Supplement Powder Stick Pack Packaging Machines Enhance Product Freshness and Convenience?

Jul 11, 2025

In the ever-evolving landscape of the food supplement industry, the demand for innovative packaging solutions has never been more critical. Among the various packaging options available, stick pack packaging has emerged as a popular choice for food supplement powders. This article explores how food supplement powder stick pack packaging machines can enhance product freshness and convenience, ultimately benefiting both manufacturers and consumers.

The Rise of Stick Pack Packaging

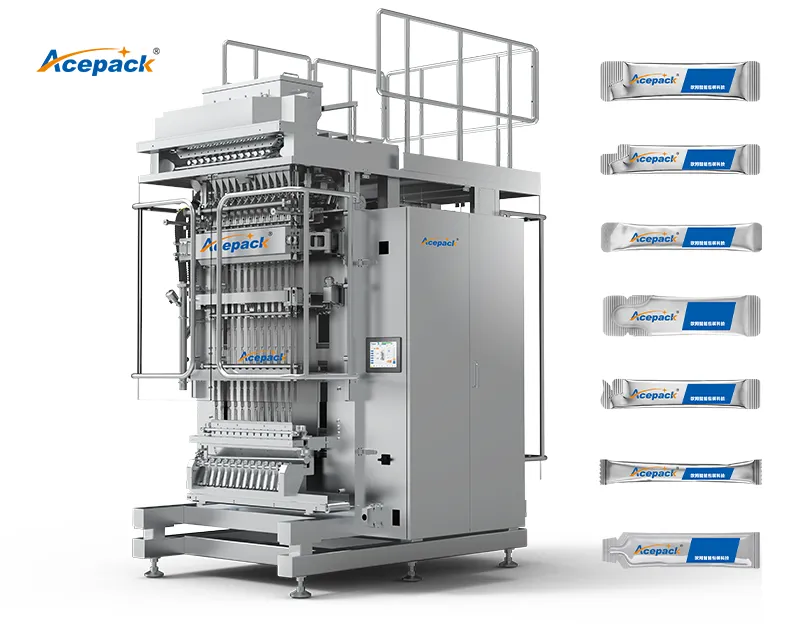

Stick pack packaging refers to a slender, flexible pouch that is typically sealed on both ends, allowing for easy dispensing of powdered products. This type of packaging has gained traction in the food supplement sector due to its numerous advantages, including portability, portion control, and ease of use. As consumers increasingly seek convenient and on-the-go solutions, stick pack packaging has become a preferred choice for manufacturers looking to meet these demands.

Enhancing Freshness

One of the primary concerns for food supplement manufacturers is maintaining the freshness and efficacy of their products. Food supplement powders are often sensitive to environmental factors such as moisture, light, and air, which can lead to degradation over time. Stick pack packaging machines are designed to address these challenges effectively.

-

Barrier Properties: Stick pack packaging is typically made from materials that offer excellent barrier properties. These materials can protect the contents from moisture, oxygen, and light, which are known to compromise the quality of food supplements. By using high-quality laminates and films, manufacturers can ensure that their products remain fresh for an extended period.

-

Sealing Technology: Advanced sealing technologies employed by stick pack packaging machines play a crucial role in preserving product freshness. Heat sealing, for instance, creates airtight seals that prevent external elements from entering the package. This not only extends the shelf life of the product but also maintains its flavor, potency, and nutritional value.

-

Controlled Atmosphere Packaging: Some stick pack machines offer controlled atmosphere packaging (CAP) options, where the air inside the package is replaced with an inert gas. This technique further minimizes oxidation and spoilage, ensuring that the food supplement powder retains its freshness until it reaches the consumer.

Convenience for Consumers

In addition to enhancing product freshness, stick pack packaging machines provide significant convenience for consumers, making them an attractive option in the competitive food supplement market.

-

Portability: Stick packs are lightweight and compact, making them easy to carry in bags, pockets, or even purses. This portability is particularly appealing to health-conscious consumers who are often on the go and want to maintain their supplement routine without the hassle of bulky containers.

-

Single-Serve Portions: Each stick pack typically contains a single serving of the food supplement powder, allowing consumers to easily control their intake. This portion control is not only convenient but also helps prevent overconsumption, making it easier for individuals to adhere to recommended dosages.

-

Ease of Use: Stick packs are designed for quick and easy consumption. Users can simply tear open the pack and pour the powder directly into water, smoothies, or other beverages. This simplicity appeals to busy lifestyles, as it eliminates the need for measuring scoops or dealing with messy containers.

-

Reduced Waste: The precise portioning of stick packs also contributes to reduced waste. Unlike larger containers that may lead to leftover product going stale or unused, stick packs ensure that consumers only use what they need, promoting sustainability in the food supplement industry.

The Role of Technology

The advancements in stick pack packaging machines have played a pivotal role in enhancing both product freshness and consumer convenience. Modern machines are equipped with state-of-the-art technology that allows for high-speed production, precise filling, and efficient sealing. This not only increases productivity for manufacturers but also ensures that the quality of the packaging is consistently high.

-

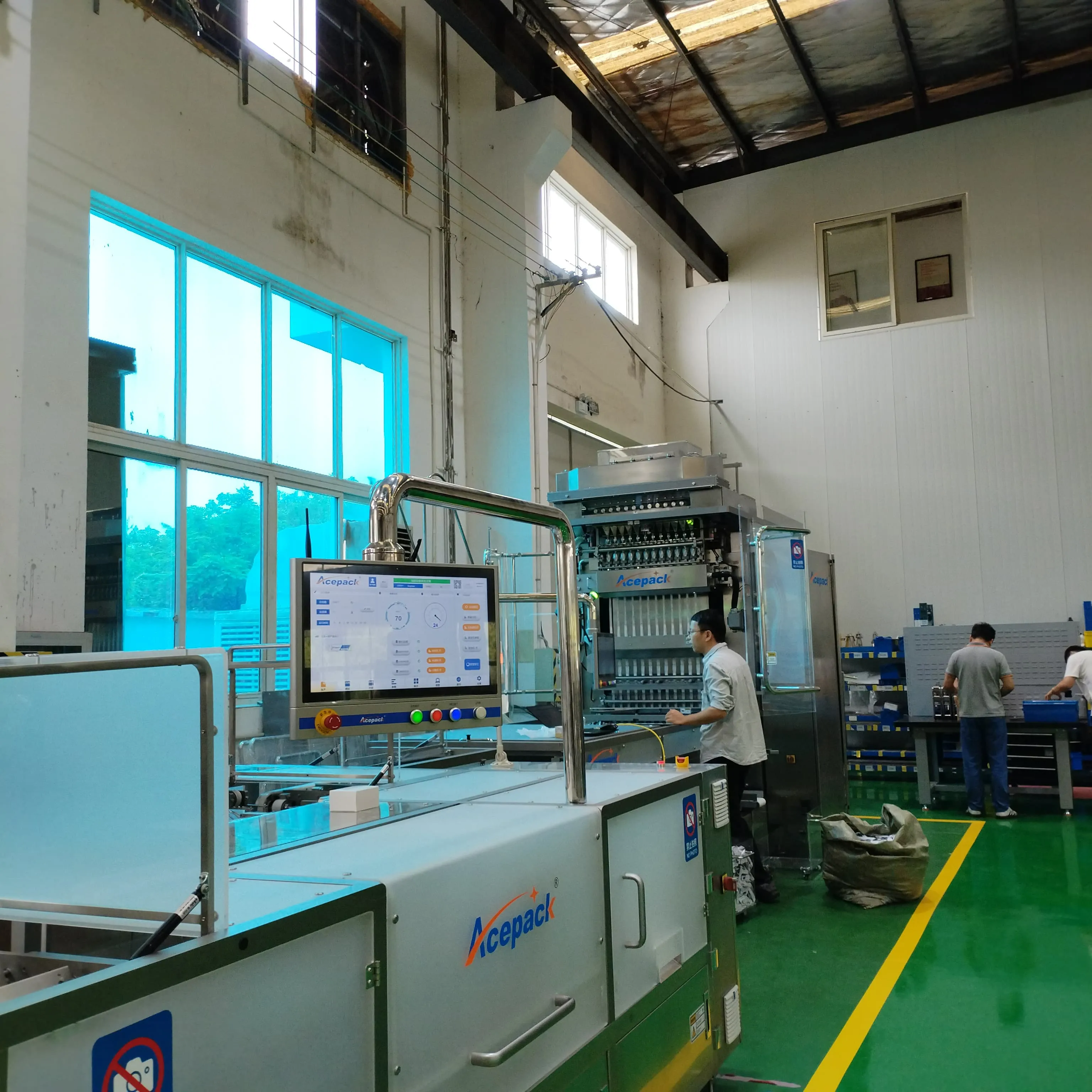

Automation: Many stick pack packaging machines are fully automated, reducing the risk of human error and increasing efficiency. Automation allows for faster production rates, which is essential for meeting the growing demand for food supplement powders.

-

Customization: Manufacturers can customize stick pack designs to suit their branding and marketing strategies. This flexibility allows for unique packaging that stands out on store shelves while still providing the functional benefits of stick packs.

-

Integration with Quality Control Systems: Advanced packaging machines can be integrated with quality control systems that monitor the packaging process in real-time. This ensures that each stick pack meets the required standards for freshness and safety, further enhancing consumer trust in the product.

Conclusion

Food supplement powder stick pack packaging machines represent a significant advancement in the packaging industry, offering solutions that enhance product freshness and convenience. By utilizing high-quality materials, advanced sealing technologies, and automation, manufacturers can ensure that their products remain fresh and effective while providing consumers with a convenient and portable option for their supplement needs. As the demand for food supplements continues to grow, stick pack packaging will undoubtedly play a crucial role in shaping the future of the industry, benefiting both manufacturers and consumers alike.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Feb 12, 2026

What can Shaped Doypack Packing Machine do?