Matcha Packaging Machines: Your Strategic Partner in Brand Building & Sustainable Growth

Jul 25, 2025

For matcha producers, packaging is far more than containment; it's the crucial first impression, a canvas for brand storytelling, and a growing arena for sustainability commitments. Modern Matcha Powder Packaging Machines are sophisticated enablers, transforming operational capability into tangible brand value and environmental responsibility. Let's delve into how this technology goes beyond basic filling and sealing.

Crafting the Premium Unboxing Experience:

Matcha consumers expect a sensory journey that begins with the package. Specialized machinery unlocks possibilities:

-

Flexible Format Mastery:

-

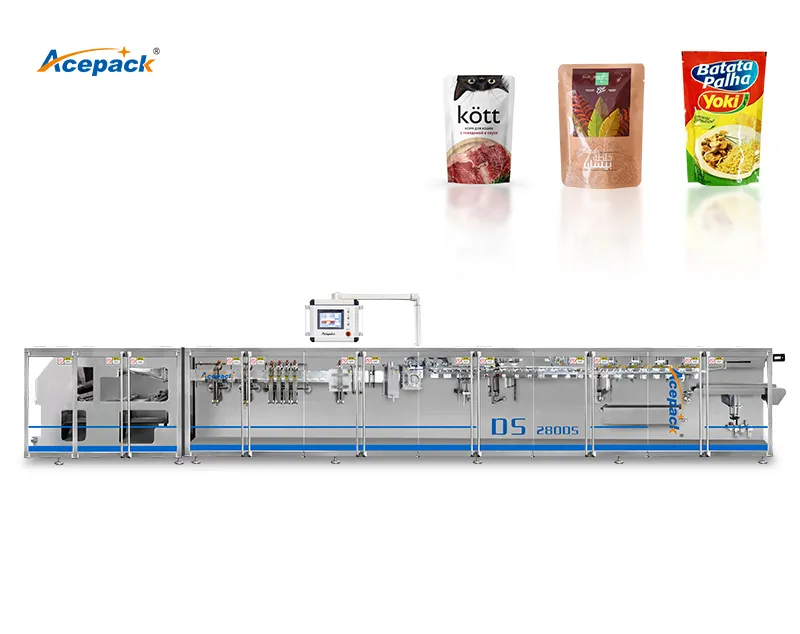

Machines adeptly handle diverse formats critical for premium positioning: sleek stand-up pouches with zippers, elegant flat-bottom pouches, rigid tins, stick packs for single-serves, and innovative shaped pouches.

-

Brand Impact: Allows choosing the perfect format to reflect brand identity – minimalist luxury, traditional craftsmanship, or modern convenience.

-

-

Enabling High-Quality Printing & Materials:

-

Precise handling mechanisms accommodate high-barrier, often thicker, laminated films necessary for matcha, which also serve as excellent substrates for vibrant, high-resolution printing.

-

Brand Impact: Showcases stunning graphics, intricate designs, and rich colors that communicate quality and brand story directly on the shelf or online.

-

-

Precision & Perfection:

-

Consistent, clean seals (fin seals, lap seals, tin sealing) and perfectly aligned labels/codes are hallmarks of automated machines.

-

Brand Impact: Projects professionalism, attention to detail, and quality assurance – subconsciously assuring the consumer of the product's integrity inside.

-

Driving Sustainability in Matcha Packaging:

Eco-conscious consumers demand responsible packaging. Modern machines facilitate this shift:

-

Compatibility with Sustainable Materials:

-

Advanced machines can be configured to run increasingly popular recyclable mono-materials (like specific PP or PE structures) or compostable films, despite their sometimes different handling characteristics.

-

Sustainability Impact: Reduces reliance on non-recyclable multi-layer laminates, aligning with circular economy goals.

-

-

Optimized Material Usage:

-

Precision forming, filling, and sealing minimize film waste during production runs.

-

Accurate filling drastically reduces product overfill waste – a significant factor with premium matcha.

-

Sustainability Impact: Lowers overall material consumption and product loss, reducing environmental footprint and cost.

-

-

Reduced Energy & Resource Consumption:

-

Efficient servo-driven motors and optimized processes consume less energy than older machines or manual packing.

-

Sustainability Impact: Contributes to lower operational carbon emissions.

-

Operational Excellence as a Brand Foundation:

Reliability and efficiency enabled by automation underpin brand reputation:

-

Uncompromising Consistency:

-

Every package matches the next – same fill weight, same seal integrity, same presentation.

-

Brand Impact: Builds consumer trust and loyalty through predictable, flawless quality.

-

-

Enhanced Traceability & Compliance:

-

Integrated coding systems (inkjet, laser) reliably print batch codes, expiry dates, and barcodes on every unit.

-

Brand Impact: Ensures regulatory compliance and enables efficient traceability for recalls or quality checks, protecting the brand.

-

-

Scalability & Responsiveness:

-

Automated lines handle increased order volumes efficiently and allow faster response to market trends (e.g., launching new sizes or limited editions).

-

Brand Impact: Ensures reliable supply to retailers and consumers, preventing stockouts that damage brand reputation.

-

Future-Proofing Your Matcha Business:

Choosing a versatile matcha powder packaging machine positions you for the future:

-

Modularity: Select machines that allow adding features later (e.g., weight checkers, vision inspection, additional gas flushing capabilities).

-

Adaptability: Look for equipment capable of handling a range of package sizes and types without excessive changeover downtime.

-

Smart Technology: Consider machines with IoT connectivity for predictive maintenance, performance monitoring, and data-driven optimization.

Conclusion:

A state-of-the-art Matcha Powder Packaging Machine is far more than a piece of factory equipment. It's a strategic asset that directly shapes brand perception through premium presentation, enables meaningful sustainability initiatives, and ensures the operational reliability that underpins customer trust. In an industry where quality, aesthetics, and ethics are paramount, the right packaging machinery is a powerful partner in building a distinctive, respected, and future-ready matcha brand. Elevate your matcha from a commodity to a covetable experience, one perfectly packaged pouch at a time.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Feb 12, 2026

What can Shaped Doypack Packing Machine do?