Maximizing ROI: The Operational Power of a Matcha Zipper Pouch Packaging Machine

Sep 09, 2025

Introduction: The Scaling Challenge for Matcha Brands

What begins as a passionate artisanal venture can quickly evolve into a complex operational challenge. As demand for your high-quality Matcha powder grows, manual or semi-automated packaging processes become a significant bottleneck. Inaccurate fills, slow speeds, high product waste due to spoilage, and inconsistent seals can erode your profit margins and hamper your ability to scale.

For growth-focused Matcha brands, operational efficiency is just as important as product quality. The bridge between these two pillars is often strategic automation. Specifically, integrating an automated zipper stand-up pouch packaging machine for Matcha is a transformative investment that pays dividends far beyond beautiful packaging.

Beyond Aesthetics: The Tangible Operational Benefits

Let’s break down how this specialized machinery directly impacts your bottom line.

1. Dramatically Increased Production Speed and Output

Manual filling and sealing of pouches is painstakingly slow. A modern, automated machine can dramatically increase your output.

-

From Hands to Automation: While a manual operator might manage 10-15 pouches per minute with fatigue, an automated system can consistently run at 40-60 pouches per minute or more, depending on the model.

-

Meeting Demand: This increased speed allows you to fulfill large orders on time, take on new clients without panic, and free up your skilled staff for more value-added tasks like quality control and marketing.

2. Unparalleled Weight Accuracy and Cost Savings

Matcha is a high-value product. Every gram overfilled is money directly lost from your pocket. Every underfilled pouch risks customer complaints and chargebacks.

-

Precision Auger Fillers: These machines use sophisticated servo-driven augers to measure powder with extreme accuracy, typically within ±0.1 grams or better.

-

The Math of Accuracy: Saving just 0.5 grams of Matcha per pouch might seem small, but over a production run of 10,000 units, that’s 5 kg of product saved. For premium Matcha, this translates to thousands of dollars in recovered revenue annually, quickly paying for the machine itself.

3. Radical Reduction in Product Waste

Waste occurs in two ways: through packaging errors and product degradation.

-

Error Reduction: Automated systems minimize spillage and mis-seals. Consistent, reliable operation means less product dumped due to packaging failures.

-

Spoilage Elimination: The integrated nitrogen flushing capability is your strongest weapon against waste. By removing oxygen, you prevent oxidation throughout the entire shelf life. This virtually eliminates returns due to stale, discolored product, protecting your brand's reputation and saving the entire cost of replaced goods.

4. Enhanced Operational Flexibility and Scalability

A great packaging machine grows with you.

-

Size Versatility: Modern machines allow for quick changeovers between different pouch sizes (e.g., from 30g sample sizes to 100g premium packs) with minimal downtime. This lets you easily expand your product line.

-

Future-Proofing: As you move into new markets with different regulatory requirements, the ability to print batch numbers, expiration dates, and barcodes directly onto the pouch seal becomes invaluable. Many machines offer integrated coding systems for this purpose.

Key Technical Considerations for Your Investment

When evaluating a zipper stand-up pouch packaging machine for Matcha, look for these operational features:

-

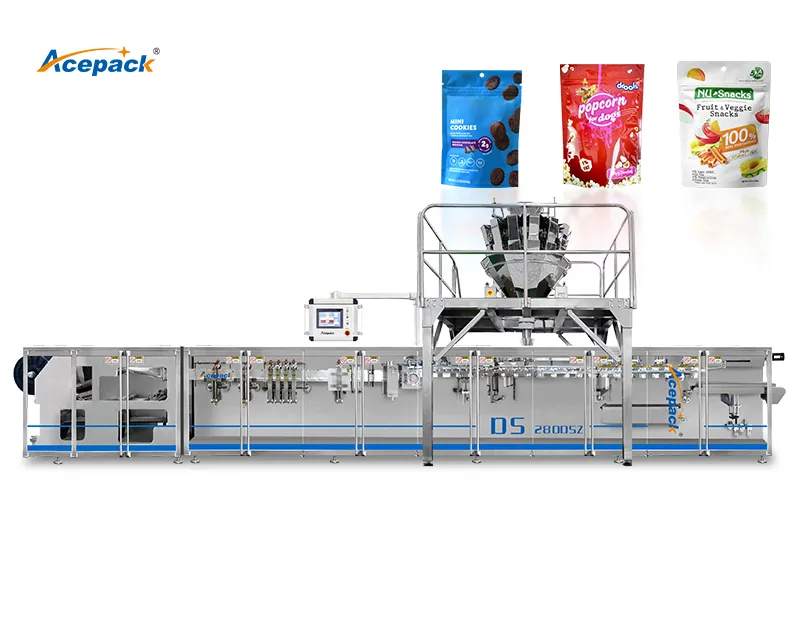

Automation Level: Decide between semi-automatic (operator loads each pouch) vs. fully automatic (pouches are fed from a roll, formed, filled, and sealed in one continuous motion). For medium to high volume, fully automatic is the path to true efficiency.

-

Integrated Nitrogen Flushing System: As emphasized, this is critical for Matcha. Ensure the machine has a powerful and precise gas flushing system.

-

User-Friendly HMI (Human-Machine Interface): A simple touchscreen control panel allows operators to easily set parameters, recall recipes for different products, and monitor machine performance.

-

Durability and Support: The machine should be built from food-grade stainless steel for durability and ease of cleaning. Equally important is the manufacturer’s reputation for technical support and availability of spare parts.

Calculating Your Return on Investment (ROI)

The initial investment in automated packaging equipment can be significant, but it must be viewed through the lens of long-term gain. A simple ROI calculation should include:

-

Labor Cost Savings: How many packaging staff hours will you save?

-

Product Savings: Calculate the value of product saved through improved accuracy and reduced spoilage.

-

Increased Revenue: Factor in your ability to handle more orders and prevent lost sales due to inadequate capacity.

-

Brand Equity: While harder to quantify, the reduction in customer complaints and enhanced brand perception have immense financial value.

For most growing brands, a well-chosen machine achieves a full ROI within 12-24 months.

Conclusion: Automate to Accelerate

Packaging is not just an end-of-line cost; it's a strategic function. For a Matcha brand, an automated zipper stand-up pouch packaging machine is the engine of scalability. It empowers you to maintain impeccable quality standards at volume, control costs with precision, and present your product in a format that consumers love and trust.

Don’t let manual processes limit your potential. Invest in packaging automation to protect your product, your profit, and your path to future growth.

.webp?x-oss-process=image/resize,w_100/quality,q_100)