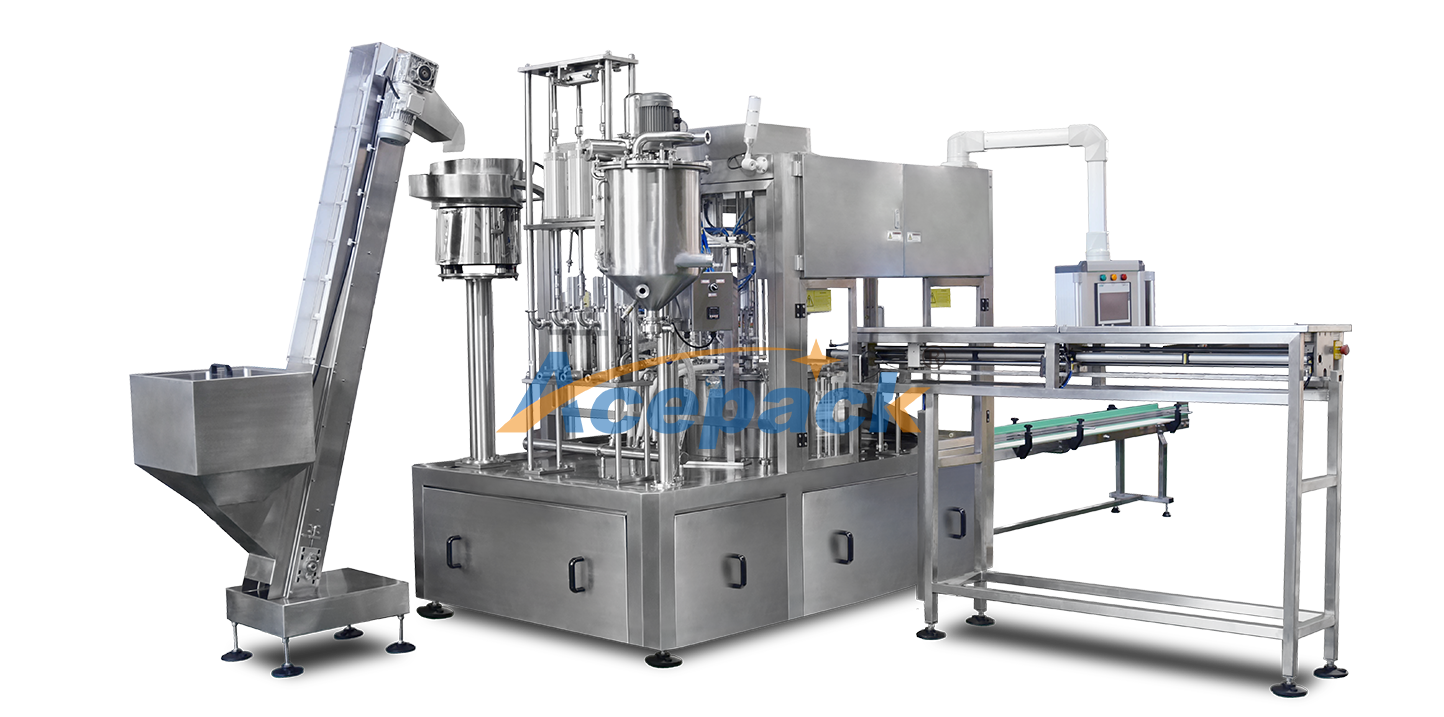

Multi-Head Filling and Capping Machines: Precision Meets Scalability

Mar 26, 2025

In industries where speed and accuracy are non-negotiable, multi-head filling and capping machines have emerged as game-changers. These machines are engineered to handle diverse liquid products—from bagged water and fruit juices to viscous condiments and cleaning agents—with unmatched consistency.

Core Advantages

- High-Speed Production: Equipped with multiple filling heads (4 to 16 heads), these machines can fill hundreds of pouches per hour, making them ideal for large-scale operations.

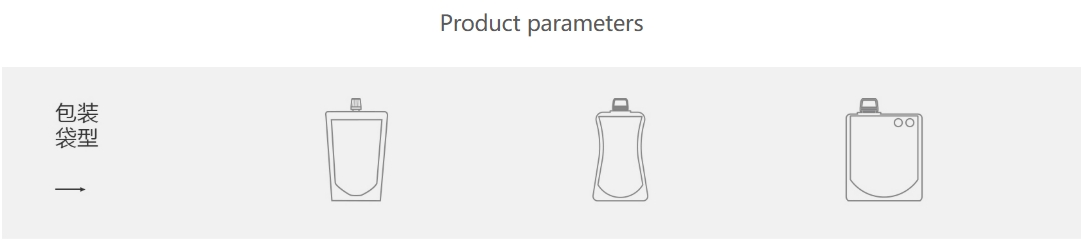

2.Flexibility: Quick-change parts allow seamless switching between pouch sizes and materials, reducing setup time.

3.Hygienic Design: Stainless steel contact surfaces comply with food-grade and pharmaceutical safety standards.

Technical Specifications

-Filling Accuracy: Utilizes load cells or flow meters to achieve precision within ±0.5–1% of the target volume.

- Sealing Methods: Options include heat sealing, induction sealing, or screw capping, depending on product requirements.

- Automation Level: Fully automated systems integrate with conveyors, labeling machines, and quality-check systems for end-to-end production lines.

Industry-Specific Benefits

- Beverage Sector: Ensures leak-proof seals for carbonated drinks and flavored waters.

- Personal Care: Safely packages shampoos, lotions, and sanitizers without contamination risks.

- Chemicals: Resistant to corrosive substances, thanks to acid-proof materials.

Maintenance and ROI

- Low Operational Costs: Energy-efficient motors and minimal manual intervention reduce overhead.

- Easy Maintenance: Modular design allows quick replacement of worn parts, minimizing downtime.

Multi-head filling and capping machines represent the pinnacle of packaging technology, offering businesses the dual benefits of scalability and precision. Their robust construction and adaptability ensure a rapid return on investment, making them indispensable for manufacturers aiming to optimize their production workflows.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Feb 12, 2026

What can Shaped Doypack Packing Machine do?