Revolutionizing Packaging Efficiency: Zipper Bag Packaging Machine

Apr 21, 2025

In the fast-paced manufacturing and packaging industries, efficiency and precision are critical. One of the most innovative solutions to emerge in recent years is the ziplock bag packaging machine. This advanced equipment is designed to streamline the packaging process, especially for products that require a secure and convenient bag. In this blog, we will explore the various components and features of the ziplock bag packaging machine, focusing on how it can transform your packaging process.

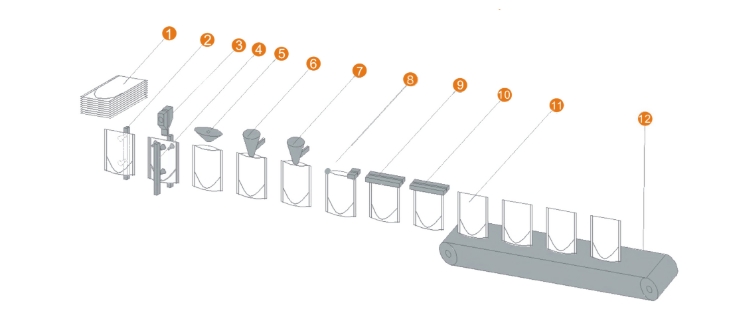

Learn about zipper bag packaging machine

The core of the ziplock bag packaging machine is designed to process pre-made bags, which are becoming increasingly popular in various industries such as food, pharmaceuticals and consumer goods. The machine is equipped with a series of advanced features to ensure efficient and reliable packaging.

1. Pre-made bag stacking

The process starts with a pre-made bag stack where the bagged bags are neatly arranged and ready for filling. This feature eliminates the need for bag forming, saving time and reducing material waste. The machine can accommodate a variety of bagged bag sizes and styles, providing flexibility for different products.

2. Flip-top bag taking device

Once the bags have been stacked, the flip bag picker comes into play. It is designed to precisely pick up and position the bags for filling. The precision of the unit ensures that each bag is handled gently, minimizing the risk of damage and ensuring a smooth transition to the filling phase.

3. Zipper opening

One of the standout features of zipper bag packaging machines is the ability to seamlessly open zipper bags. For products that require easy access for consumers, the zipper opening mechanism is essential. This feature not only enhances the user experience, but also ensures that the bag is filled correctly without compromising the integrity of the zipper.

4. Open the bag

In addition to the zipper opening, the machine is also equipped with a bag opening system suitable for a variety of bag types. This flexibility allows manufacturers to use different bag designs without the need for multiple machines, thus optimizing production efficiency.

Filling process

The filling process is where the zipper bag packaging machine really shines. It incorporates a variety of advanced technologies to ensure that each bag can be filled accurately and efficiently.

5. Air flushing

Before filling, the machine uses an air flushing system to remove any contaminants from the bag. This step is particularly important for food and pharmaceutical products, as hygiene requirements for these products are crucial. The air flushing process ensures that the bag is clean and easy to fill, thereby reducing the risk of product spoilage.

6. First filling

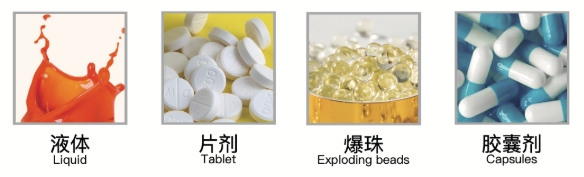

The first filling stage is the dispensing of the primary product into the packaging bags. The machine is equipped with a sophisticated filling mechanism that can handle a wide range of product types from powders to liquids. This versatility makes it suitable for a wide range of applications.

7. Second filling

For products that require multiple components or multi-layer packaging, zipper bag packaging machines offer a secondary filling option. This feature allows manufacturers to add other ingredients or products to the same bag, thereby enhancing the value and appeal of the product.

8. Bag stretching

To ensure the bags reach their maximum capacity, the machine is equipped with a bag stretching device that allows the bag to expand slightly during the filling process, thus accommodating more product without compromising the integrity of the bag.

Sealing and finishing touches

Once the filling process is complete, the ziplock bag packaging machine will proceed to seal the bag securely.

9. Top Seal I and 10. Top Seal II

The machine is equipped with two sealing mechanisms: Top Seal I and Top Seal II. These seals ensure that the bag is airtight and tamper-proof, thus maintaining the freshness and safety of the product. The double sealing process provides an extra layer of security, ideal for sensitive products.

11. Finished Product

After sealing, the bag is ready for distribution. Ziplock bag packaging machines ensure consistent seal and fill quality for each bag, maintaining high quality standards throughout the entire production process.

12. Export

Finally, the finished bags are delivered to the discharge port for easy collection and preparation for packaging or shipping. The efficient discharge port design minimizes processing time and ensures a smooth transition from production to distribution.

in conclusion

The Ziplock Pouch Packaging Machine is a game-changer in the packaging industry. With advanced features including pre-made pouch stacking, precise filling mechanisms and secure sealing options, it provides manufacturers with a reliable and efficient packaging solution. By investing in this innovative equipment, businesses can increase productivity, reduce waste and ultimately provide customers with superior products. As the demand for convenient and safe packaging continues to grow, the Ziplock Pouch Packaging Machine has become a key tool for success in the modern market.

.webp?x-oss-process=image/resize,w_100/quality,q_100)