Revolutionizing Packaging: The Power of Fully Automatic Horizontal Form Fill Seal Machines

Jun 13, 2025

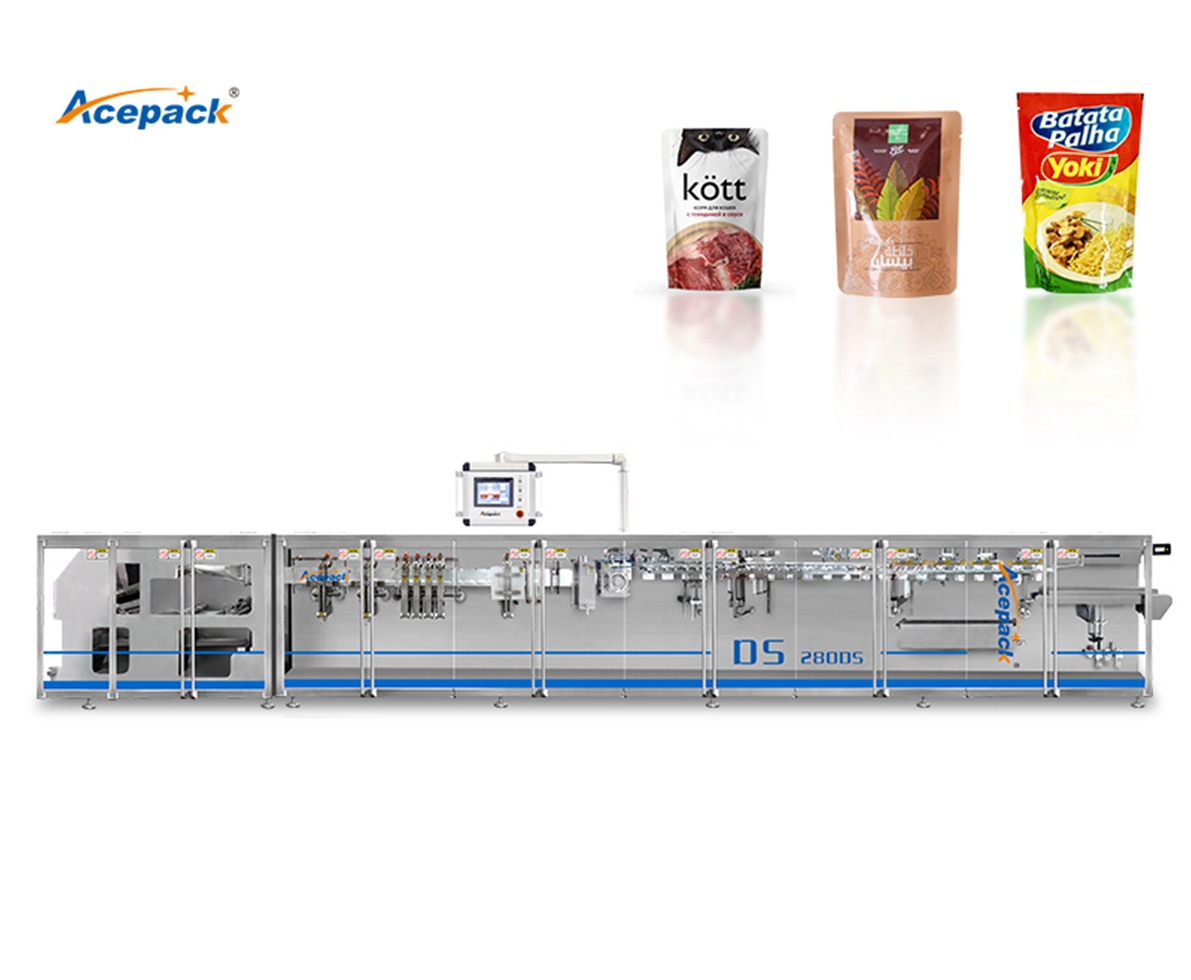

In the fast-paced world of packaging, efficiency and versatility are paramount. As businesses strive to meet the ever-increasing demands of consumers, the need for advanced packaging solutions has never been more critical. Enter the fully automatic horizontal form fill seal (HFFS) machines, a game-changer in the realm of stand-up pouch packaging. These machines are designed to streamline the entire process of forming, filling, and sealing pouches, making them an indispensable asset for manufacturers across various industries.

What is a Fully Automatic Horizontal Form Fill Seal Machine?

A fully automatic horizontal form fill seal machine is a sophisticated piece of equipment that automates the entire packaging process for stand-up pouches. Unlike traditional packaging methods that require multiple steps and manual labor, HFFS machines integrate all necessary functions into one seamless operation. This not only enhances productivity but also ensures consistent quality and reduces the risk of human error.

Key Features of HFFS Machines

-

Versatile Packaging Options: One of the standout features of fully automatic HFFS machines is their ability to accommodate a wide range of pouch types. Whether you need stand-up pouches, special-shaped sachets, spouted stand-up pouches, zipper pouches, or even pouches with hanging holes, these machines can handle it all. This versatility makes them ideal for businesses that offer diverse product lines.

-

Multiple Filling Systems: HFFS machines are equipped with various filling systems, allowing them to pack different types of materials, including powders, liquids, and granules. This adaptability is crucial for manufacturers who need to package a variety of products, from food items to pharmaceuticals.

-

Fully Automatic Operation: The fully automatic nature of these machines means that once they are set up, they can operate independently, significantly reducing the need for manual intervention. This not only saves time but also allows staff to focus on other critical areas of production.

-

High-Speed Production: In today’s competitive market, speed is essential. HFFS machines are designed for high-speed production, enabling manufacturers to meet tight deadlines and increasing their overall output. This efficiency can lead to significant cost savings and improved profit margins.

-

User-Friendly Interface: Modern HFFS machines come equipped with intuitive control panels that make it easy for operators to monitor and adjust settings. This user-friendly design minimizes the learning curve and ensures that even less experienced staff can operate the machinery effectively.

The Benefits of Using HFFS Machines

1. Enhanced Efficiency

The integration of forming, filling, and sealing processes into a single machine drastically reduces the time and labor required for packaging. This efficiency translates into faster turnaround times and the ability to respond quickly to market demands.

2. Consistent Quality

With automated processes, HFFS machines ensure that each pouch is formed, filled, and sealed to the same high standard. This consistency is vital for maintaining brand reputation and customer satisfaction.

3. Reduced Waste

By optimizing the packaging process, HFFS machines help minimize material waste. Precise filling systems ensure that the right amount of product is used, reducing overfilling and spillage.

4. Cost-Effectiveness

While the initial investment in HFFS technology may be significant, the long-term savings in labor costs, material waste, and increased production efficiency make it a cost-effective solution for many businesses.

5. Flexibility for Future Growth

As businesses evolve, so do their packaging needs. HFFS machines offer the flexibility to adapt to new products and packaging styles, ensuring that manufacturers can pivot quickly in response to market trends.

Industries Benefiting from HFFS Machines

The versatility of fully automatic horizontal form fill seal machines makes them suitable for a wide range of industries, including:

- Food and Beverage: From snacks to sauces, HFFS machines can package a variety of food products in stand-up pouches that are both functional and visually appealing.

- Pharmaceuticals: The precision and hygiene standards required in the pharmaceutical industry make HFFS machines an ideal choice for packaging medications and supplements.

- Cosmetics and Personal Care: With the rise of e-commerce, the demand for attractive and functional packaging in the cosmetics industry has surged, making HFFS machines a valuable asset.

- Household Products: Cleaning supplies and other household items can also benefit from the efficiency and versatility of HFFS machines.

Conclusion

In conclusion, fully automatic horizontal form fill seal machines are revolutionizing the packaging industry by offering a comprehensive solution for stand-up pouch packaging. Their ability to automate the entire process, accommodate various pouch types, and handle different filling materials makes them an invaluable tool for manufacturers looking to enhance efficiency and maintain product quality. As businesses continue to adapt to changing market demands, investing in HFFS technology will undoubtedly provide a competitive edge in the ever-evolving landscape of packaging.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Feb 12, 2026

What can Shaped Doypack Packing Machine do?