Shanghai Acepack: Leading the Way in Premade Bag Packing

Dec 05, 2025

In the fast - paced era, industries like food, medicine, and daily chemicals are seeing rapid product turnover. Consumers also have higher expectations for product packaging. Traditional manual or semi - automatic packaging methods are inefficient and produce inconsistent quality, struggling to meet modern production needs. Shanghai Acepack has stepped in with its self - developed premade bag packing machines, offering a brand - new automated packaging solution.

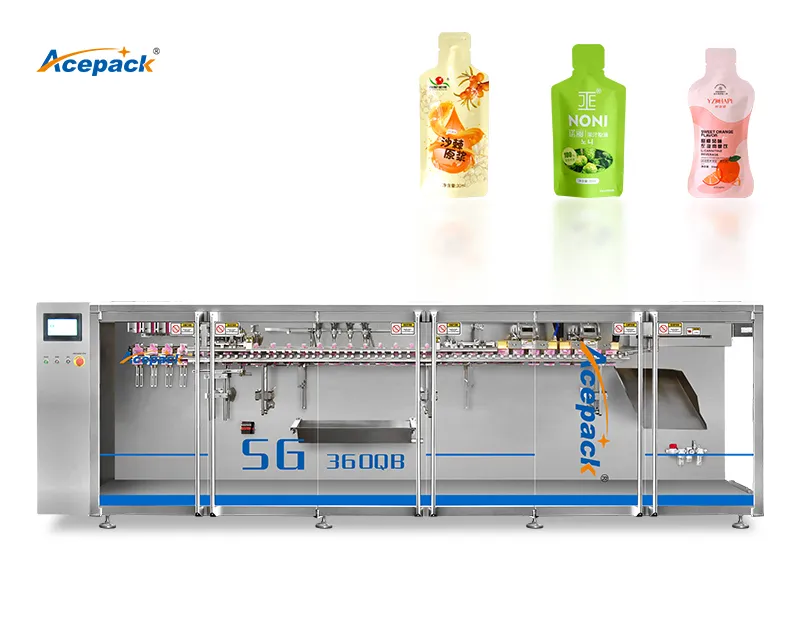

These premade bag packing machines from Shanghai Acepack are like tireless packaging assistants. They use advanced robotic arms or vacuum suction systems to automatically place bags at designated spots. Whether it's common PE bags, aluminum foil bags, or special ones like self - standing bags and spout bags, they handle them with ease. Changing bag types is a breeze, with a 60% reduction in changeover time compared to traditional equipment, saving a lot of production preparation time.

When it comes to packaging accuracy, they shine. Each machine has a metering system tailored to different materials. For nuts, through visual positioning and a counting device, the error in the number of nuts per bag is within ±1, ensuring almost equal quantities in each bag. For sauces, with a flat - layout design and vacuum extraction technology, the vacuum error inside the bags is no more than 1.5%, better preserving the sauces and extending their shelf life.

Shanghai Acepack's machines are also versatile, applicable in over 30细分领域 (sub - fields). In the food industry, for fragile items like potato chips and nuts, they have soft - gripping and buffering devices, protecting the food during packaging. When packaging hot pot seasoning, they use high - temperature - resistant materials and rapid - cooling sealing technology to prevent leaks. A dairy company saw a 25% increase in production line efficiency and a 40% reduction in labor costs after introducing these machines, recovering the investment in less than a year.

In the medicine field, the machines are equipped with sterile chambers and negative - pressure filtration systems, meeting GMP certification requirements. For high - end health products, visual positioning technology enables precise "small - bag - in - large - bag" arrangements, enhancing product appearance and value.

In the daily chemicals industry, for liquid products like shampoos and laundry detergents, they use pump - sending systems and anti - drip designs to speed up filling. For powdered detergents, dust covers and negative - pressure dust removal devices keep the workshop clean by controlling dust levels.

Shanghai Acepack is also committed to environmental protection. Its machines use energy - saving motors and waste heat recovery technology, reducing energy consumption compared to traditional models. They also work well with eco - friendly materials, helping companies cut plastic use and pollution. A seasoning company reduced its defect rate from 3% to 0.5% and cut plastic use by 12 tons a year after switching to degradable packaging and using Shanghai Acepack's machines.

Looking ahead, Shanghai Acepack will continue to innovate, driving premade bag packing machines towards greater intelligence. Since its establishment in 2005, it has served clients in over 70 countries and regions, making these machines a great helper for companies on the road to intelligent manufacturing.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor