The Future of Packaging: Candy Form-Fill-Seal Pouch Packaging Machines

Aug 21, 2025

What is a Candy Form-Fill-Seal Pouch Packaging Machine?

In the world of confectionery, packaging plays a crucial role in preserving freshness, enhancing shelf appeal, and ensuring convenience for consumers. But what exactly is a Candy Form-Fill-Seal Pouch Packaging Machine? This innovative piece of equipment is designed to automate the process of forming, filling, and sealing pouches specifically for candy products. By streamlining production, these machines not only save time but also reduce labor costs and minimize waste.

How Does a Candy Form-Fill-Seal Pouch Packaging Machine Work?

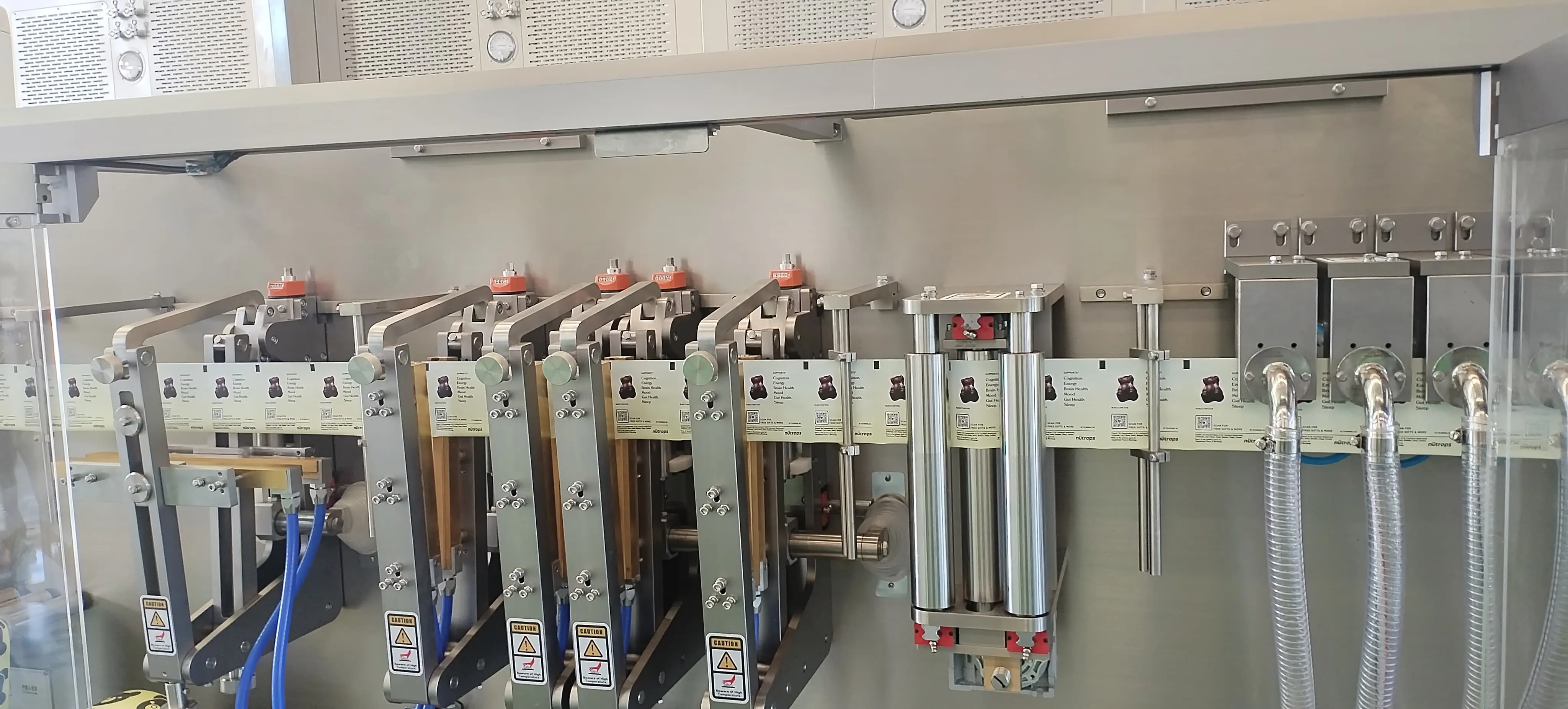

Have you ever wondered how these machines operate? The process begins with a roll of flexible packaging material, which is fed into the machine. The machine then forms the material into a pouch shape, fills it with the desired candy, and seals it shut—all in one continuous operation. This efficiency is what makes the Candy Form-Fill-Seal Pouch Packaging Machine a popular choice among manufacturers.

Why Choose Pouch Packaging for Candy?

What are the advantages of using pouches for candy packaging? Pouches offer several benefits over traditional packaging methods. They are lightweight, which reduces shipping costs, and they can be designed with resealable features, enhancing convenience for consumers. Additionally, pouches can be printed with vibrant graphics, making them visually appealing on store shelves. This combination of practicality and aesthetics makes pouch packaging an attractive option for candy manufacturers.

What Types of Candy Can Be Packaged?

Are you curious about the versatility of these machines? Candy Form-Fill-Seal Pouch Packaging Machines can handle a wide variety of candy types, including gummies, chocolates, hard candies, and even granola bars. This adaptability allows manufacturers to switch between products with minimal downtime, making it easier to respond to market trends and consumer preferences.

How Do These Machines Ensure Product Freshness?

Have you ever thought about how packaging affects the freshness of candy? One of the key features of Candy Form-Fill-Seal Pouch Packaging Machines is their ability to create airtight seals. This prevents moisture and air from entering the pouch, which can lead to spoilage or staleness. By maintaining a controlled environment, these machines help ensure that candy products remain fresh for longer periods, ultimately enhancing customer satisfaction.

What Are the Key Features to Look For?

When considering a Candy Form-Fill-Seal Pouch Packaging Machine, what features should you prioritize? Look for machines that offer adjustable fill volumes, customizable pouch sizes, and easy-to-use controls. Additionally, consider machines that are equipped with advanced technology, such as sensors for detecting pouch integrity and automated cleaning systems. These features can significantly improve efficiency and reduce the risk of errors during production.

How Do These Machines Contribute to Sustainability?

Is sustainability a concern for your business? Many manufacturers are now prioritizing eco-friendly practices, and Candy Form-Fill-Seal Pouch Packaging Machines can play a role in this effort. By using less material than traditional packaging methods, these machines can help reduce waste. Furthermore, advancements in biodegradable and recyclable packaging materials mean that manufacturers can offer environmentally friendly options without sacrificing quality or performance.

What Are the Cost Implications?

Are you wondering about the financial investment required for a Candy Form-Fill-Seal Pouch Packaging Machine? While the initial cost may seem high, the long-term savings can be substantial. By automating the packaging process, manufacturers can reduce labor costs and increase production speed. Additionally, the reduction in material waste and improved product shelf life can lead to higher profit margins. When considering the return on investment, many businesses find that these machines pay for themselves over time.

How Can You Choose the Right Machine for Your Needs?

What factors should you consider when selecting a Candy Form-Fill-Seal Pouch Packaging Machine? Start by assessing your production volume and the types of candy you plan to package. It’s also essential to evaluate the available space in your facility, as some machines can be quite large. Finally, consider the level of technical support and training offered by the manufacturer, as this can significantly impact your operational efficiency.

What Does the Future Hold for Candy Packaging?

What trends are shaping the future of candy packaging? As consumer preferences continue to evolve, manufacturers must stay ahead of the curve. Innovations in packaging technology, such as smart packaging that incorporates QR codes or augmented reality, are becoming increasingly popular. Additionally, the demand for healthier and more sustainable candy options is driving changes in packaging materials and designs. By investing in advanced Candy Form-Fill-Seal Pouch Packaging Machines, manufacturers can position themselves for success in this dynamic market.

Conclusion: Is It Time to Invest in a Candy Form-Fill-Seal Pouch Packaging Machine?

In conclusion, the Candy Form-Fill-Seal Pouch Packaging Machine represents a significant advancement in the confectionery industry. With its ability to streamline production, enhance product freshness, and offer sustainable packaging solutions, it’s an investment worth considering. As you weigh your options, remember to evaluate your specific needs and the potential return on investment. The future of candy packaging is bright, and with the right machinery, your business can thrive in this competitive landscape.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Feb 12, 2026

What can Shaped Doypack Packing Machine do?