Understanding the Stand-Up Pouch Filling Machine: How It Works and Its Benefits

May 23, 2025

In the world of packaging, efficiency and convenience are paramount. One of the most innovative solutions that have emerged in recent years is the stand-up pouch filling machine. This technology has revolutionized the way products are packaged, offering a blend of functionality and aesthetic appeal. In this blog, we will explore how a stand-up pouch filling machine works, its benefits, and why it has become a preferred choice for many manufacturers.

What is a Stand-Up Pouch?

Before diving into the mechanics of the filling machine, it’s essential to understand what a stand-up pouch is. A stand-up pouch is a flexible packaging solution that can stand upright on shelves, thanks to its bottom gusset. These pouches are typically made from multiple layers of materials, including plastic and aluminum, which provide durability and barrier properties to protect the contents from moisture, light, and air. Stand-up pouches are commonly used for packaging snacks, pet food, coffee, and various other products.

How Does a Stand-Up Pouch Filling Machine Work?

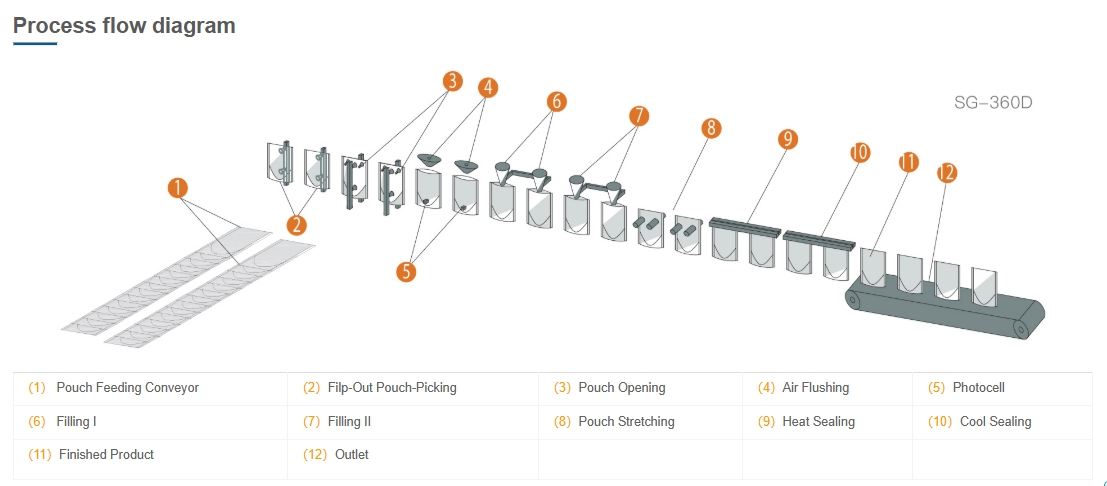

The stand-up pouch filling machine is designed to automate the process of filling these pouches with various products. Here’s a step-by-step breakdown of how it works:

-

Pouch Loading: The process begins with the loading of empty stand-up pouches into the machine. Depending on the model, this can be done manually or automatically. The machine is equipped with a feeding system that ensures the pouches are correctly positioned for filling.

-

Pouch Opening: Once the pouches are in place, the machine uses a series of mechanical arms or vacuum systems to open the pouches. This step is crucial as it prepares the pouch for the filling process.

-

Filling: After the pouches are opened, the filling mechanism comes into play. This can vary based on the type of product being filled. For dry products like snacks, a volumetric filler may be used, while liquid products may require a pump system. The filling process is highly precise, ensuring that each pouch receives the correct amount of product.

-

Sealing: Once the pouches are filled, they move to the sealing station. Here, the machine uses heat sealing or cold sealing methods to close the pouches securely. This step is vital for maintaining the freshness of the product and preventing contamination.

-

Quality Control: After sealing, the pouches undergo quality control checks. This may include weight checks, visual inspections, and leak tests to ensure that each pouch meets the required standards.

-

Packaging and Labeling: Finally, the filled and sealed pouches are packaged for distribution. Many stand-up pouch filling machines also come equipped with labeling systems that can print and apply labels to the pouches, streamlining the entire process.

Benefits of Using a Stand-Up Pouch Filling Machine

The adoption of stand-up pouch filling machines offers numerous advantages for manufacturers:

-

Efficiency: Automating the filling process significantly increases production speed. This efficiency allows manufacturers to meet high demand without compromising quality.

-

Cost-Effectiveness: While the initial investment in a stand-up pouch filling machine may be substantial, the long-term savings in labor costs and increased production output can lead to a favorable return on investment.

-

Versatility: Stand-up pouch filling machines can handle a wide range of products, from powders and granules to liquids and pastes. This versatility makes them suitable for various industries, including food and beverage, pharmaceuticals, and cosmetics.

-

Enhanced Shelf Appeal: Stand-up pouches are visually appealing and can be designed with vibrant graphics and branding. This aesthetic advantage can help products stand out on store shelves, attracting more customers.

-

Sustainability: Many stand-up pouches are made from recyclable materials, making them a more environmentally friendly option compared to traditional packaging. Additionally, their lightweight design reduces shipping costs and carbon footprints.

-

Improved Product Freshness: The sealing process used in stand-up pouch filling machines ensures that products remain fresh for longer periods. The barrier properties of the pouches protect against moisture and oxygen, extending shelf life.

Conclusion

The stand-up pouch filling machine is a game-changer in the packaging industry. Its ability to efficiently fill, seal, and label pouches makes it an invaluable asset for manufacturers looking to enhance their production processes. With the added benefits of cost-effectiveness, versatility, and sustainability, it’s no wonder that stand-up pouches have become a popular choice for packaging a wide range of products. As technology continues to evolve, we can expect even more innovations in the realm of stand-up pouch filling machines, further streamlining the packaging process and meeting the demands of consumers and manufacturers alike.

In summary, understanding how a stand-up pouch filling machine works not only highlights its importance in modern packaging but also showcases the potential for growth and efficiency in various industries. Whether you are a manufacturer or a consumer, the impact of this technology is undeniable, paving the way for a more efficient and sustainable future in packaging.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Feb 12, 2026

What can Shaped Doypack Packing Machine do?