What is a 4-Side Sealing HFFS Packaging Machine? A Detailed Overview

Oct 16, 2025

In the fast-paced world of packaging, efficiency and reliability are paramount. The 4-side sealing HFFS packaging machine stands out as a versatile solution for various industries, offering seamless packaging with enhanced protection. But what exactly is this machine, and why is it gaining popularity? This article delves into the fundamentals of 4-side sealing HFFS packaging machines, explaining their operation, benefits, and real-world applications. By the end, you'll understand how this technology can revolutionize your packaging processes, ensuring durability and cost-effectiveness. Whether you're in food, pharmaceuticals, or consumer goods, this guide provides actionable insights to help you leverage this advanced equipment.

What is a 4-Side Sealing HFFS Packaging Machine?

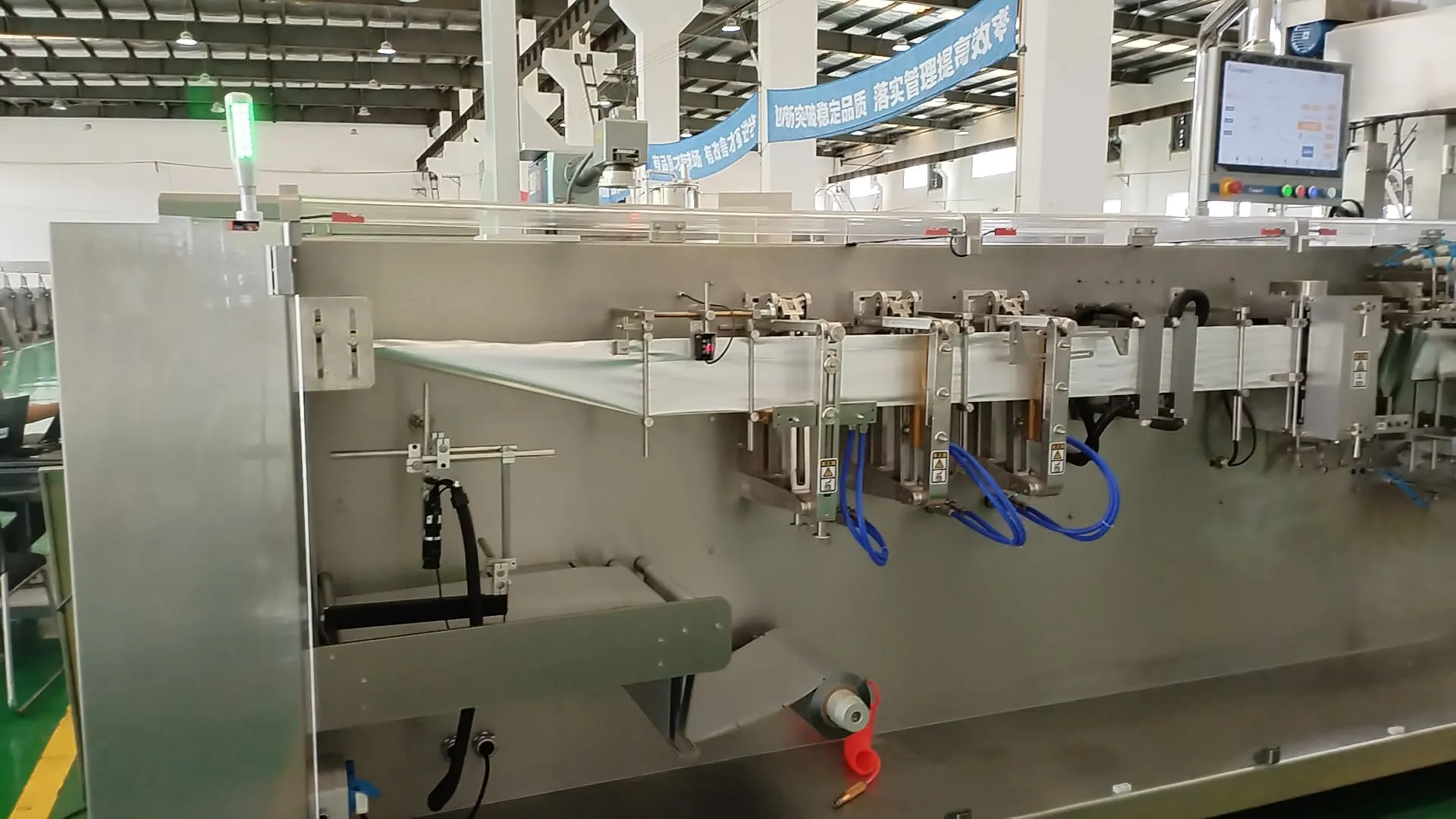

A 4-side sealing HFFS packaging machine is a type of horizontal form fill seal (HFFS) system that creates packages sealed on all four sides. Unlike traditional machines that might leave edges exposed, this design ensures complete enclosure, protecting contents from moisture, contaminants, and physical damage. The term "HFFS" refers to the process where the machine forms a pouch from a roll of film, fills it with the product, and seals it horizontally. The 4-side sealing aspect adds an extra layer of security by sealing the top, bottom, and both sides, resulting in a robust, tamper-evident package. This machine is ideal for items requiring high hygiene standards, such as medical supplies or perishable foods, as it minimizes human intervention and reduces the risk of errors. How does this compare to other packaging methods? It offers superior seal integrity and faster production rates, making it a preferred choice for high-volume operations.

How Does a 4-Side Sealing HFFS Machine Work?

The operation of a 4-side sealing HFFS packaging machine involves a series of automated steps that ensure precision and speed. First, a flat roll of packaging material—often laminated films or composites—is fed into the machine. The film is then formed into a tube shape, and the longitudinal seals are created along the edges using heat or pressure. Next, the product is dispensed into the formed pouch through a filling system, which can handle solids, liquids, or powders. After filling, the machine seals the top and bottom transversely, completing the four-side enclosure. This process is controlled by programmable logic controllers (PLCs) and sensors that monitor parameters like temperature and speed to maintain consistency. Why is this workflow so efficient? It reduces material waste and allows for rapid changeovers between different package sizes, catering to flexible production needs. Additionally, modern versions integrate IoT capabilities for real-time monitoring, further enhancing productivity and reducing downtime.

What are the Key Advantages of Using a 4-Side Sealing HFFS Packaging Machine?

Adopting a 4-side sealing HFFS packaging machine brings numerous benefits that can transform your packaging line. Firstly, it offers enhanced product protection by creating a hermetic seal that guards against external factors like oxygen, humidity, and pests. This is crucial for extending shelf life in food and pharmaceutical industries. Secondly, the machine boosts efficiency through high-speed operation, capable of producing hundreds of packages per minute. This scalability makes it suitable for both small businesses and large corporations. Thirdly, it reduces operational costs by minimizing material usage and labor requirements. How does it achieve this? The precise sealing mechanisms prevent overuse of films, and automation cuts down on manual handling. Moreover, the machine supports sustainability efforts by enabling the use of recyclable materials and reducing packaging waste. Other advantages include improved hygiene, as the closed system limits contamination, and versatility in handling various products, from snacks to chemicals. By investing in this technology, companies can achieve higher ROI and meet evolving market demands.

Where is the 4-Side Sealing HFFS Packaging Machine Commonly Used?

The versatility of the 4-side sealing HFFS packaging machine makes it applicable across multiple sectors. In the food industry, it is widely used for packaging items like chips, cookies, and frozen foods, where airtight seals preserve freshness and prevent spoilage. The pharmaceutical sector relies on it for blister packs and sterile products, ensuring compliance with strict regulatory standards. Consumer goods, such as electronics and household items, benefit from the tamper-resistant features that enhance customer trust. How does it adapt to different environments? These machines can be customized with features like nitrogen flushing for sensitive products or anti-static coatings for electronic components. Additionally, industries like agriculture and cosmetics utilize them for seeds, fertilizers, and creams, respectively. The machine's ability to handle diverse materials—from polypropylene to foil—makes it a go-to solution for global supply chains. By understanding these applications, businesses can identify opportunities to integrate this technology for improved outcomes.

How to Choose the Right 4-Side Sealing HFFS Machine for Your Needs?

Selecting the appropriate 4-side sealing HFFS packaging machine requires careful consideration of several factors. Start by assessing your production volume: high-speed models are ideal for large-scale operations, while compact versions suit smaller batches. Next, evaluate the types of products you handle—whether they are fragile, liquid, or granular—as this influences the filling and sealing mechanisms. Material compatibility is another key aspect; ensure the machine supports your preferred packaging films to avoid compatibility issues. Why is customization important? Look for features like adjustable temperature controls, easy-to-clean designs, and user-friendly interfaces to match your specific needs. Additionally, consider the total cost of ownership, including maintenance and energy consumption. Partnering with reputable manufacturers who offer training and support can streamline the integration process. By conducting a thorough needs analysis, you can invest in a machine that delivers long-term value and aligns with your business goals.

In conclusion, the 4-side sealing HFFS packaging machine is a game-changer in modern packaging, offering durability, efficiency, and adaptability. By addressing common questions through this guide, we hope to empower you to make informed decisions for your packaging strategies. Embrace this technology to stay competitive in an ever-evolving market.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Feb 12, 2026

What can Shaped Doypack Packing Machine do?