What is the Cost of a Flat Pouch Packaging Machine?

Apr 16, 2025

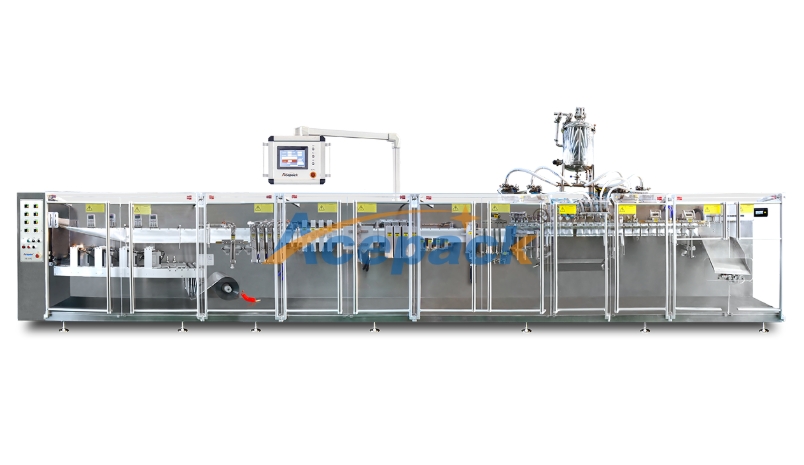

The flat pouch packaging machine stands out as a versatile and efficient solution for businesses looking to streamline their packaging processes. This machine is particularly well-suited for industries that require high-speed packaging of various products, from food items to pharmaceuticals. But as companies consider investing in this technology, a common question arises: what is the cost of a flat pouch packaging machine?

Understanding Flat Pouch Packaging Machines

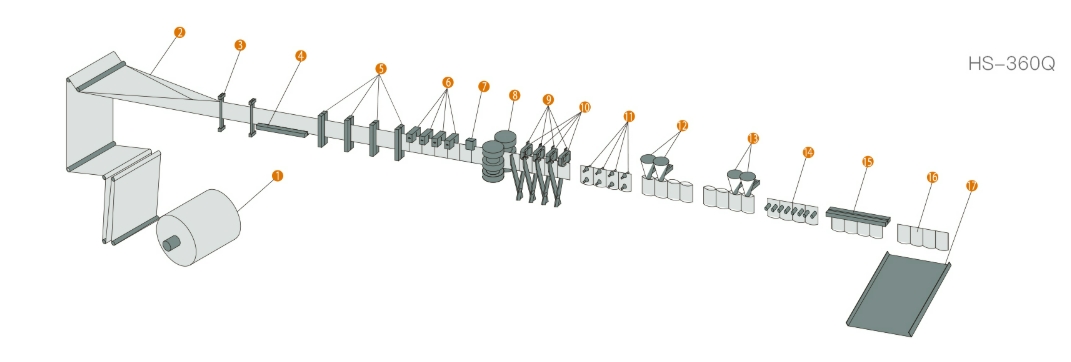

Before delving into the costs, it’s essential to understand what a flat pouch packaging machine is and how it operates. The horizontal high-speed packaging model is designed to work with various heat-sealing multi-layer composite films. This adaptability allows businesses to package a wide range of products efficiently.

One of the standout features of this machine is its ability to produce multiple bags simultaneously. This is made possible by a newly designed multi-bagging mechanism that enhances productivity and reduces operational time. Additionally, the flat pouch packaging machine integrates several functions, including bag making, measuring, and filling, making it a multi-functional model that can cater to diverse packaging needs.

Factors Influencing the Cost

The cost of a flat pouch packaging machine can vary significantly based on several factors:

-

Machine Specifications: The specific features and capabilities of the machine play a crucial role in determining its price. High-speed models with advanced technology and automation tend to be more expensive than basic models. For instance, machines that can handle various film types and sizes will generally cost more due to their versatility.

-

Production Capacity: Machines designed for high-volume production will typically come with a higher price tag. Businesses that require a machine capable of producing thousands of pouches per hour will need to invest more upfront compared to those with lower production needs.

-

Customization Options: Many manufacturers offer customization options to meet specific business requirements. Custom features, such as specialized filling systems or unique sealing mechanisms, can increase the overall cost of the machine.

-

Brand and Manufacturer: The reputation and reliability of the manufacturer can also influence pricing. Established brands with a history of quality and service may charge a premium for their machines, while newer or less-known brands might offer more competitive pricing.

-

After-Sales Support and Warranty: The level of after-sales support, including maintenance services and warranty options, can also affect the cost. Machines that come with comprehensive support packages may have a higher initial cost but can save businesses money in the long run through reduced downtime and maintenance expenses.

Average Cost Range

While the cost of a flat pouch packaging machine can vary widely, businesses can expect to pay anywhere from $20,000 to $100,000 or more, depending on the factors mentioned above. Entry-level machines suitable for small to medium-sized operations may start at the lower end of this range, while high-end, fully automated models designed for large-scale production can reach the upper limits.

Return on Investment

When considering the cost of a flat pouch packaging machine, it’s essential to evaluate the potential return on investment (ROI). Investing in a high-quality packaging machine can lead to significant cost savings over time. By increasing production efficiency, reducing labor costs, and minimizing material waste, businesses can recoup their initial investment relatively quickly.

Moreover, the ability to produce high-quality, attractive packaging can enhance product appeal and boost sales. In competitive markets, having a reliable and efficient packaging solution can be a game-changer, allowing businesses to meet customer demands and stay ahead of the competition.

The cost of a flat pouch packaging machine is influenced by various factors, including machine specifications, production capacity, customization options, brand reputation, and after-sales support. While the initial investment can be substantial, the long-term benefits of increased efficiency, reduced costs, and improved product presentation make it a worthwhile consideration for businesses in need of effective packaging solutions.

As companies weigh their options, it’s crucial to conduct thorough research and consult with manufacturers to find the best machine that fits their specific needs and budget. With the right flat pouch packaging machine, businesses can enhance their packaging processes and ultimately drive growth and success in their respective markets.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Feb 12, 2026

What can Shaped Doypack Packing Machine do?