How Do I Choose a Packing Machine?

May 19, 2025

The Ultimate Packaging Machine Selection Guide

Selecting optimal packaging machinery requires careful analysis of technical requirements and business objectives. Follow this structured approach:

Step 1: Product Analysis

Physical characteristics (viscosity, abrasiveness)

Sensitivity requirements (sterile, moisture-proof)

Step 2: Output Requirements

| Production Scale | Recommended Machine Type |

| <100 units/hr | Semi-automatic tabletop |

| 100-500 units/hr | Linear automated system |

| >500 units/hr | Rotary multi-head configuration |

Critical Selection Factors

1.Material Compatibility

Powder: Auger filler with anti-static coating

Liquids: Overflow filler with drip recovery

2.Automation Level

Basic: Manual loading + auto sealing (15k−40k)

Advanced: Robotics integration + AI quality control ($200k+)

3.Regulatory Compliance

Food grade: 316L stainless steel surfaces

Pharmaceutical: CIP/SIP capabilities

Cost-Benefit Analysis

Consider total cost of ownership:

Initial purchase price (15-25%)

Maintenance (10-15%)

Energy consumption (20-30%)

Labor savings (30-50%)

Common Mistakes to Avoid

✘ Overestimating production needs

✘ Ignoring future product diversification

✘ Choosing incompatible sealing methods

Supplier Evaluation Checklist

✓ 24/7 technical support availability

✓ On-site installation services

✓ Spare parts inventory localisation

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Feb 12, 2026

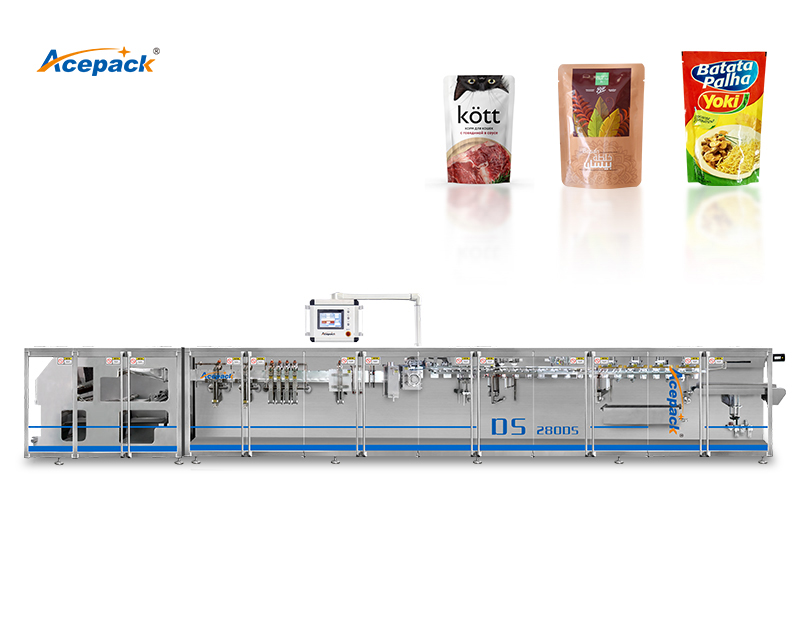

What can Shaped Doypack Packing Machine do?