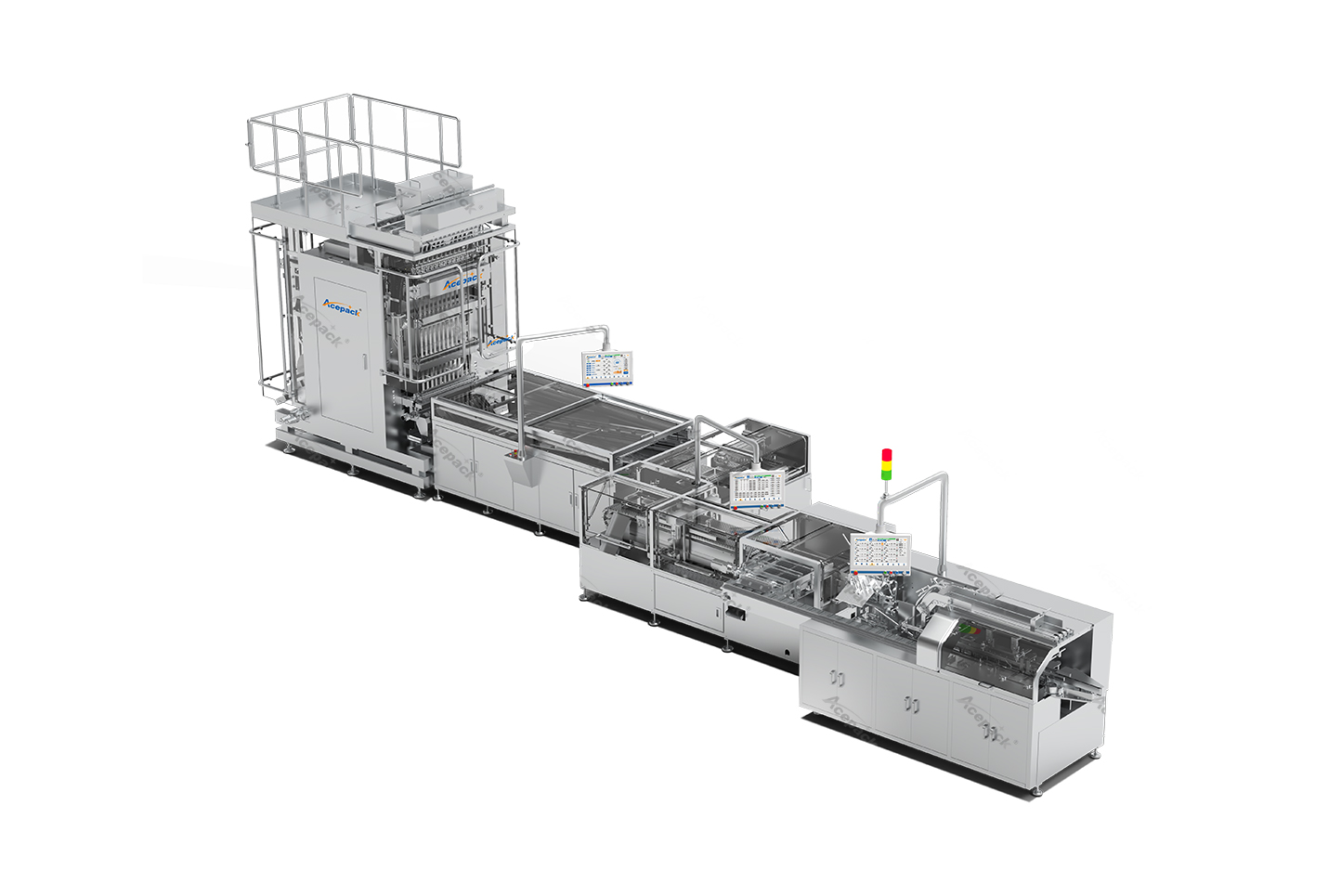

Multi-row packaging machine: An efficient leader in the field of automated packaging. How can it help companies reduce costs and increase efficiency?

May 15, 2025

Multi-row packaging machine: How can the efficient leader in the automated packaging industry reduce costs and increase efficiency for enterprises?

Introduction: "Involution" and Breakthrough in the Packaging Industry

In the fast-moving consumer goods, pharmaceutical, health care products and other industries, packaging efficiency directly affects corporate profits. Traditional single-row packaging machines can only complete hundreds of packages per hour. Faced with the multiple pressures of a surge in e-commerce orders, rising labor costs, and stricter environmental protection policies, companies are in urgent need of an "efficient and combat-capable" automated equipment - multi-row machines, which are becoming the "efficiency nuclear weapon" of the production line.

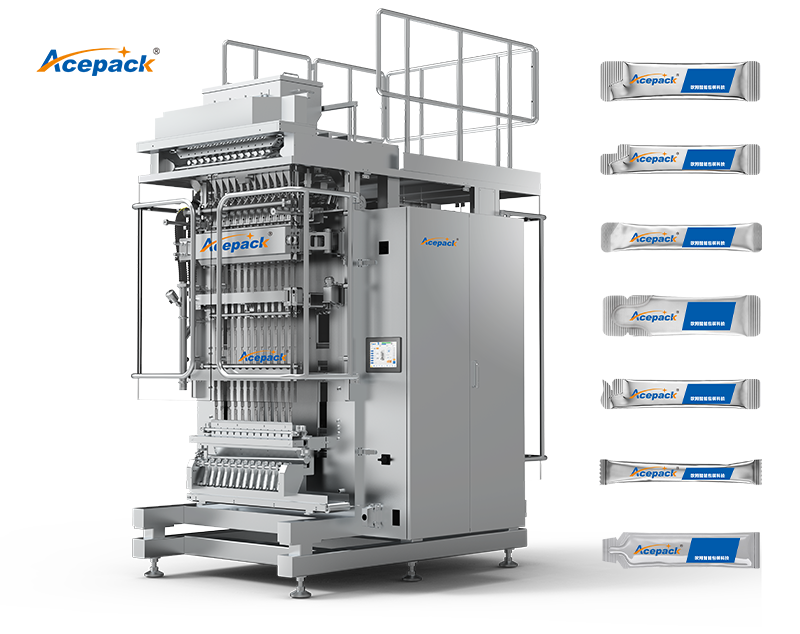

1. What is a multi-row machine? Why is it called the "octopus in the packaging industry"?

A multi-row machine is an automated equipment that achieves high-speed packaging through multi-station synchronous operation. It can complete independent packaging of 2-16 rows of products at the same time, just like a "mechanical arm version of an octopus". The production capacity of a single device is equivalent to that of 3-5 traditional devices.

Core advantage analysis:

Double efficiency: Taking coffee powder packaging as an example, a single-row machine can produce 1,200 packages per hour, and a four-row machine can reach 4,800 packages, with an efficiency increase of 300%.

Uncompromising precision: Using high-precision stepper motor + photoelectric sensor, ±0.5mm error control, avoiding customer complaints caused by "leaking powder" and "empty bag".

Flexible compatibility: From granules (coffee beans, wolfberries), powders (milk powder, Chinese medicine powder) to liquids (oral liquids), special-shaped tablets (pills), one machine can adapt to more than 80% of packaging needs.

Cost-reducing black technology:

Manpower saving: 1 multi-row machine = 1 operator + 1 quality inspector, saving more than 150,000 yuan in labor costs per year;

Reducing consumables: By optimizing the bag design (such as back seal, three-side seal), the cost of consumables is reduced by 20%.

2. How do multi-row machines "roll" industry changes?

Scenario 1: Food industry - from "slow work and fine work" to "blitzkrieg"

Pain point: Nut brands need to process 50 tons of raw materials every day, and traditional equipment has a backlog of inventory due to low efficiency.

Solution: After a leading brand introduced an eight-row machine, the production line efficiency increased by 4 times, the order delivery cycle was shortened from 7 days to 2 days, and the storage cost was reduced by 35%.

Scenario 2: Pharmaceutical industry - "millimeter-level" precision protects the lifeline

Pain point: Pharmaceutical companies need to meet the dual standards of "0.5g error ≤0.01g per package" and "100,000-level clean workshop".

Solution: The customized multi-row machine adopts a fully enclosed stainless steel cavity + online weighing and rejection system, and the defective rate is reduced from 1.2% to 0.03%, and it has passed FDA certification.

Scenario 3: Daily chemical industry - small packages leverage the big market

Pain point: The demand for cosmetic samples has exploded, but traditional equipment cannot adapt to micro-packaging below 5ml.

Solution: The ultra-high-speed multi-row machine is equipped with a micro-feeding system, and a single package of 0.2g mask powder is accurately packaged, helping the new product to exceed one million sales in the first month of its launch.

3. Selection and avoidance guide: How to avoid being cut by the "parameter trap"?

Beware of "false number of columns":

Inferior equipment: nominally "six-column machine" but only 4 columns are actually running synchronously, and the other 2 columns are for decoration;

True multi-column machine: all stations are independently driven, and the failure of any column does not affect other channels.

Material determines life:

Low price trap: ordinary carbon steel + spray painting process is used, and it will rust and be scrapped after 3 months;

High-quality materials: 304 stainless steel + food-grade silicone contact parts, passed the EU CE certification, and the life span exceeds 10 years.

Look at service rather than price:

Must-ask questions:

Do you provide free proofing tests?

Can you respond to national after-sales within 72 hours?

Does the spare parts inventory cover core components (such as cutters, sensors)?

4. Future trends: How can multi-column machines evolve into "smart packaging hubs"?

AI visual quality inspection:

Integrated industrial camera + deep learning algorithm, real-time detection of sealing wrinkles and pattern offset, with a misjudgment rate of <0.001%.

Modular assembly:

Users can replace the unloading device like "building Lego", and switch the packaging form (from bag to strip) in 1 hour.

Green packaging revolution:

Supports seamless switching between degradable film (such as PLA) and composite film, helping enterprises to cope with the "plastic restriction order".

V. Conclusion: Choosing the right multi-column machine is like choosing the right "money printing machine"

At a time when labor costs are increasing by 8% per year and customer delivery time is compressed by 40%, multi-column machines are not only equipment, but also a "strategic weapon" for enterprise transformation. Whether it is a food factory owner, a pharmaceutical company production director, or an e-commerce supply chain manager, investing in a multi-column machine is essentially paying for the competitiveness in the next five years.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Feb 12, 2026

What can Shaped Doypack Packing Machine do?