How Tomato Ketchup Sachet Packing Machines are Transforming the Food Industry

Jun 20, 2025

In the ever-evolving landscape of the food industry, efficiency, quality, and customization are paramount. One of the most significant innovations contributing to these goals is the Tomato Ketchup Sachet Packing Machine. These machines are not just a trend; they are revolutionizing how food products, particularly condiments like tomato ketchup, are packaged and delivered to consumers.

The Rise of Sachet Packaging

Sachet packaging has gained immense popularity in recent years, particularly in the food sector. This method offers convenience, portion control, and reduced waste, making it an attractive option for both consumers and manufacturers. Tomato ketchup, a staple condiment in households and restaurants alike, is now frequently found in single-serving sachets. This shift is largely driven by the demand for on-the-go solutions and the need for food products that can be easily transported and stored.

Advanced Technology in Packing Machines

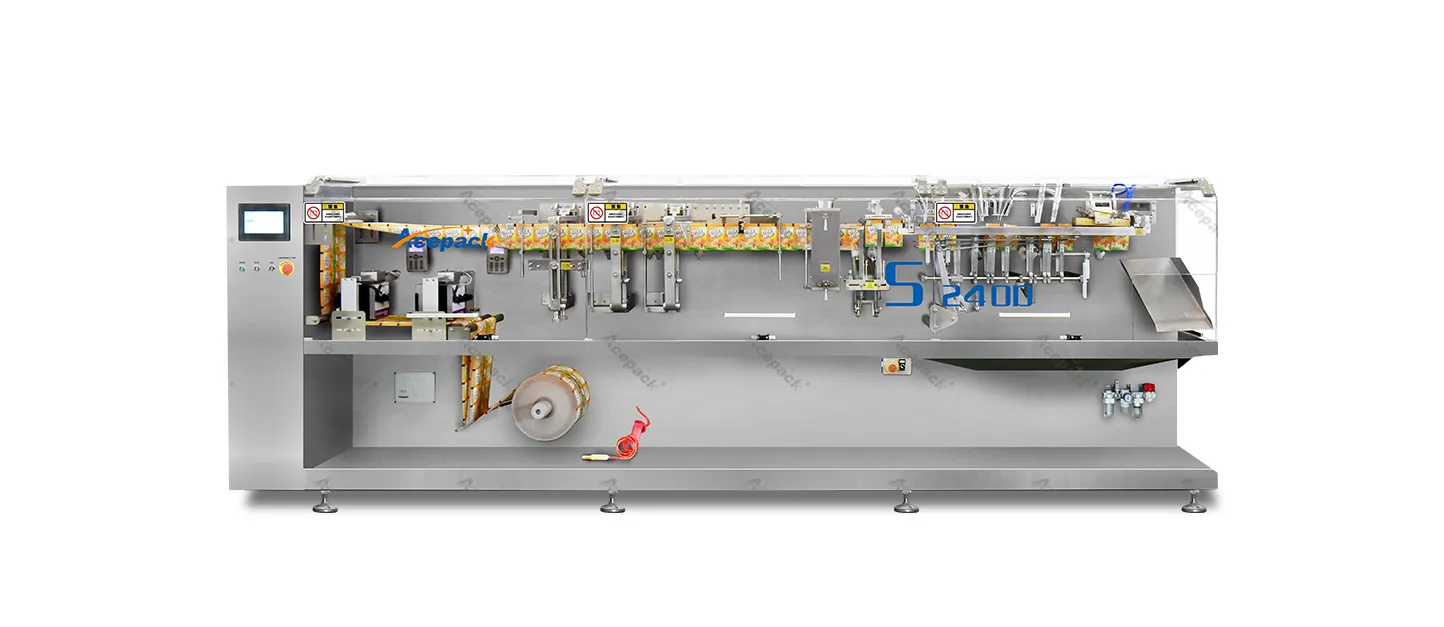

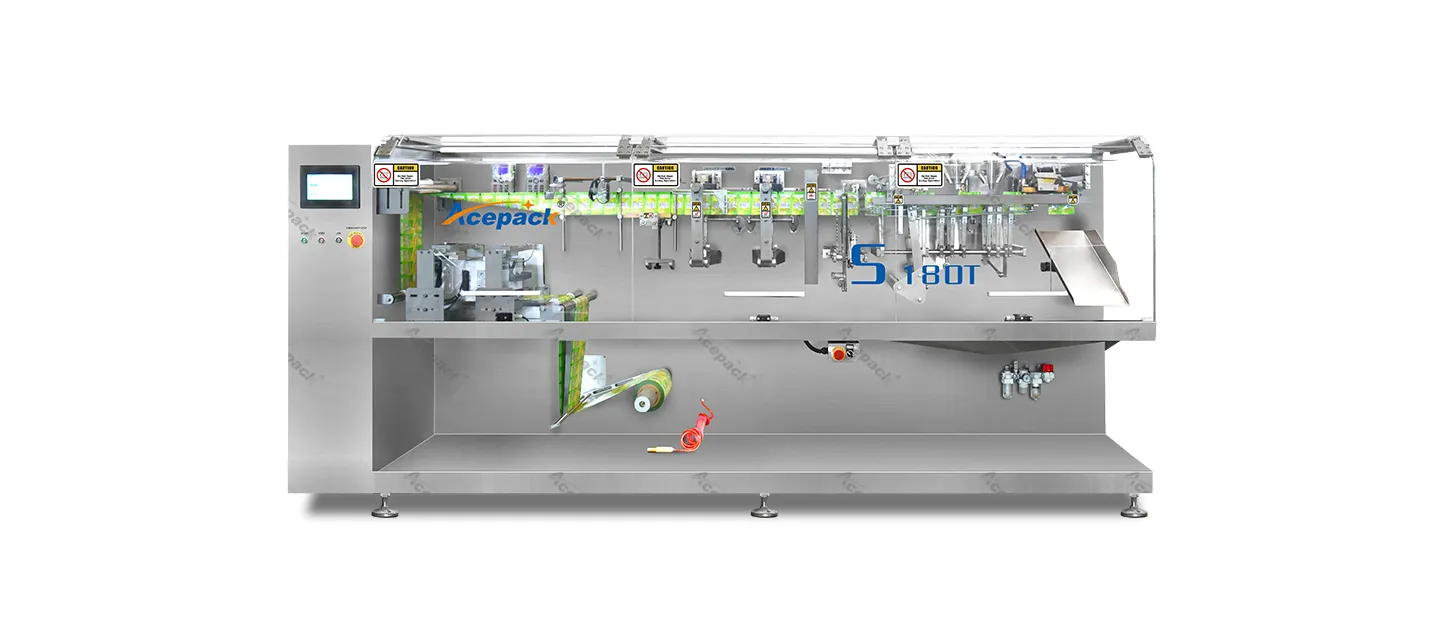

At the heart of this transformation are the Tomato Ketchup Sachet Packing Machines, which incorporate advanced technology to enhance production efficiency and product quality. These machines are designed to achieve various customized metering methods, ensuring that each sachet contains the perfect amount of ketchup. This precision is crucial for maintaining consistency and meeting consumer expectations.

One of the standout features of these machines is the 18.5-inch large industrial control screen. This user-friendly interface allows operators to monitor and control the packing process with ease. The newly designed human-machine interface (HMI) full servo control system further enhances operational efficiency, allowing for quick adjustments and real-time data analysis. This level of control not only improves the overall equipment effectiveness (OEE) but also ensures compliance with Environmental, Health, and Safety (EHS) management requirements.

Speed and Efficiency

In a fast-paced food industry, speed is of the essence. Tomato Ketchup Sachet Packing Machines are engineered to operate at stable speeds of 70-80 cuts per minute. This high throughput is essential for manufacturers looking to meet increasing consumer demand without compromising on quality. The ability to produce large quantities of sachets in a short time frame allows businesses to scale their operations and respond swiftly to market trends.

Customization and Flexibility

One of the most significant advantages of these packing machines is their ability to provide customized end-to-end solutions. Each business has unique requirements, and the flexibility of these machines allows manufacturers to tailor their packaging processes to meet specific needs. Whether it’s adjusting the size of the sachets, the amount of ketchup dispensed, or the design of the packaging, these machines can accommodate a wide range of specifications.

This level of customization is particularly beneficial in a market where consumer preferences are constantly changing. For instance, as more consumers seek healthier options, manufacturers can easily adapt their packaging to highlight organic or low-sugar ketchup variants. This adaptability not only helps businesses stay relevant but also enhances their competitive edge.

Supporting Automation in Production

The integration of Tomato Ketchup Sachet Packing Machines into production lines supports the broader trend of automation in the food industry. Automation reduces labor costs, minimizes human error, and increases overall productivity. With the ability to operate autonomously, these machines free up human resources for more complex tasks, allowing businesses to optimize their workforce.

Moreover, the data statistics capabilities of these machines provide valuable insights into production processes. By analyzing this data, manufacturers can identify areas for improvement, streamline operations, and ultimately enhance profitability. The incorporation of electronic signatures and audit trails also ensures that quality control measures are upheld, further solidifying the integrity of the production process.

Conclusion

The Tomato Ketchup Sachet Packing Machine is more than just a piece of equipment; it is a transformative force in the food industry. By combining advanced technology, speed, customization, and automation, these machines are redefining how tomato ketchup and other condiments are packaged. As consumer preferences continue to evolve, the ability to adapt and innovate will be crucial for manufacturers looking to thrive in a competitive market.

In summary, the impact of Tomato Ketchup Sachet Packing Machines extends beyond mere packaging. They represent a shift towards greater efficiency, quality, and consumer satisfaction in the food industry. As businesses embrace these innovations, they are not only enhancing their production capabilities but also paving the way for a more sustainable and responsive food supply chain. The future of food packaging is here, and it is undoubtedly shaped by the advancements in sachet packing technology.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Feb 12, 2026

What can Shaped Doypack Packing Machine do?