Prompt response: Upon receiving your inquiry, a professional sales engineer will promptly communicate with you to understand your specific needs.

Tailored solutions: Our sales engineers not only grasp your packaging requirements but also provide suggestions based on their extensive experience with related products.

Rich case experience: Our sales engineers have dealt with various cases and possess a deep understanding of the precautions involved in packing different types of powders, granules, and liquids into various bag types.

Involvement of project engineers: For non-standard projects, our project engineers will participate in evaluating your project and offer the most reasonable and cost-effective solution.

Comprehensive technical support: Our sales engineers and project engineers are committed to providing comprehensive technical support, ensuring that you receive satisfactory packaging solutions.

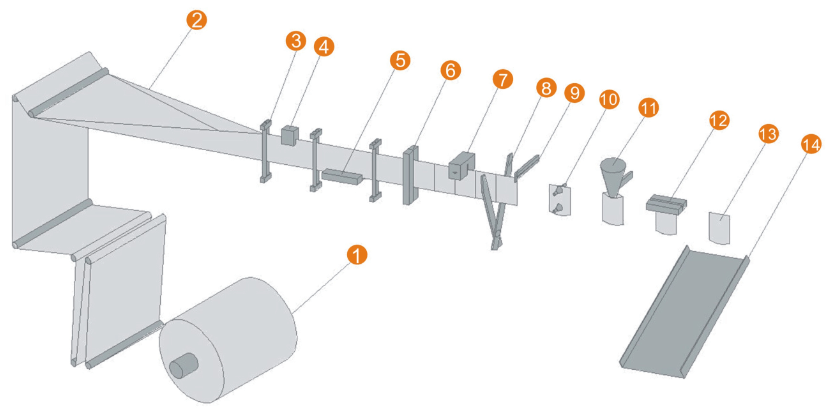

Standard Sachet Packing Machine

Technical Parameter

|

Modle |

S-110 |

S-130 |

S-180 |

S-240 |

|

Pouch Size |

50*50mm(Min) |

50*80mm(Min) |

50*80mm(Min) |

100*120mm(Min) |

|

Filling capacity |

60ml |

260ml |

400ml |

1000ml |

|

Packing capacity |

40-80ppm |

40-80ppm |

40-80ppm |

30-70ppm |

|

Powder |

2KW |

3.5KW |

4.5KW |

5.5KW |

|

Air consumption |

0NL/min |

100NL/min |

200NL/min |

300NL/min |

|

Machine Dimensions |

2060mm(L) |

2850mm(L) |

3500mm(L) |

4600mm(L) |

|

Weight |

520kg |

900kg |

1400kg |

2000kg |

|

Function |

3 side seal, |

3 side seal, |

3 side seal, |

3 side seal, |

Finished Bag Photo