Prompt response: Upon receiving your inquiry, a professional sales engineer will promptly communicate with you to understand your specific needs.

Tailored solutions: Our sales engineers not only grasp your packaging requirements but also provide suggestions based on their extensive experience with related products.

Rich case experience: Our sales engineers have dealt with various cases and possess a deep understanding of the precautions involved in packing different types of powders, granules, and liquids into various bag types.

Involvement of project engineers: For non-standard projects, our project engineers will participate in evaluating your project and offer the most reasonable and cost-effective solution.

Comprehensive technical support: Our sales engineers and project engineers are committed to providing comprehensive technical support, ensuring that you receive satisfactory packaging solutions.

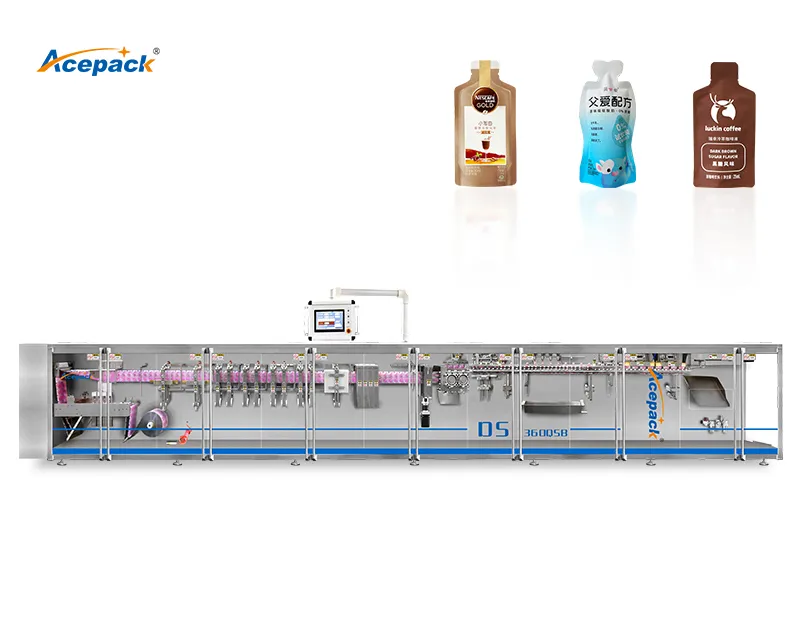

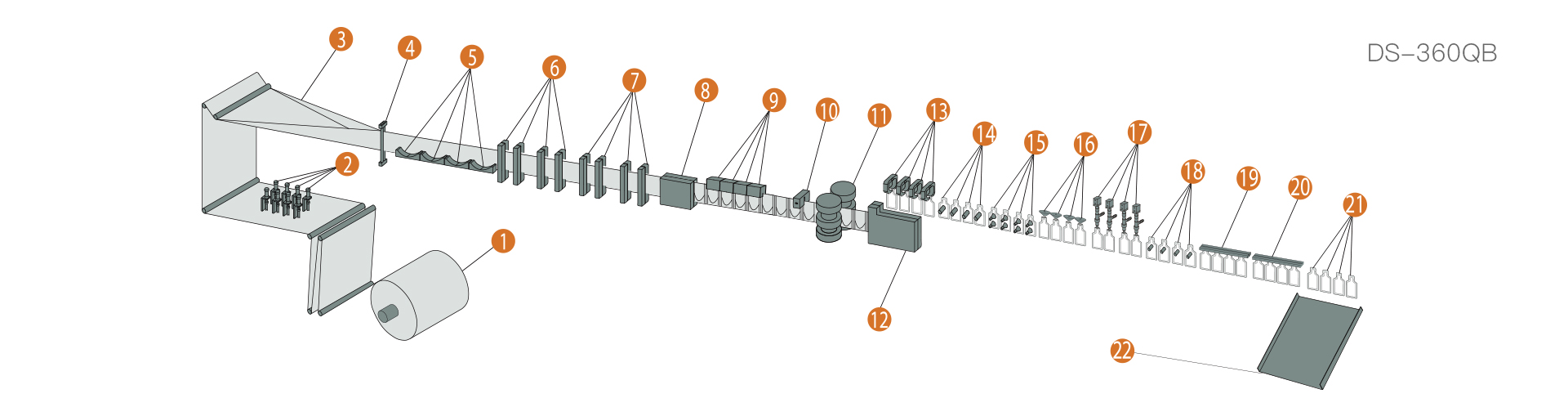

Shaped Doypack Packing Machine

Technical Parameter

|

Model |

DS-360Q(B) |

DS-180DS(B) |

DS-140S(B) |

|

Maximum Packing Volume |

150ml |

150ml |

300ml |

|

Max Pouch Size |

90mm*180mm |

90mm*180mm |

140mm*200mm |

|

Min Pouch Size |

60mm*100mm |

60mm*100mm |

60mm*90mm |

|

Packing Speed |

160-200ppm |

80-120ppm |

40-60ppm |

|

Air Consumption |

800NL/min |

600NL/min |

500NL/min |

|

Input Power |

17kw |

8.3kw |

6.5Kw |

|

Working Power Supply |

AC 380V 50Hz |

AC 380V 50Hz |

AC 380V 50Hz |

|

Equipment Weight |

6000kg |

2200kg |

1600kg |

|

L*W*H |

9800*1050*1400mm |

5630*970*1400mm |

4480*970*1400mm |

Acepack's Tailored, High-Performance Solution:

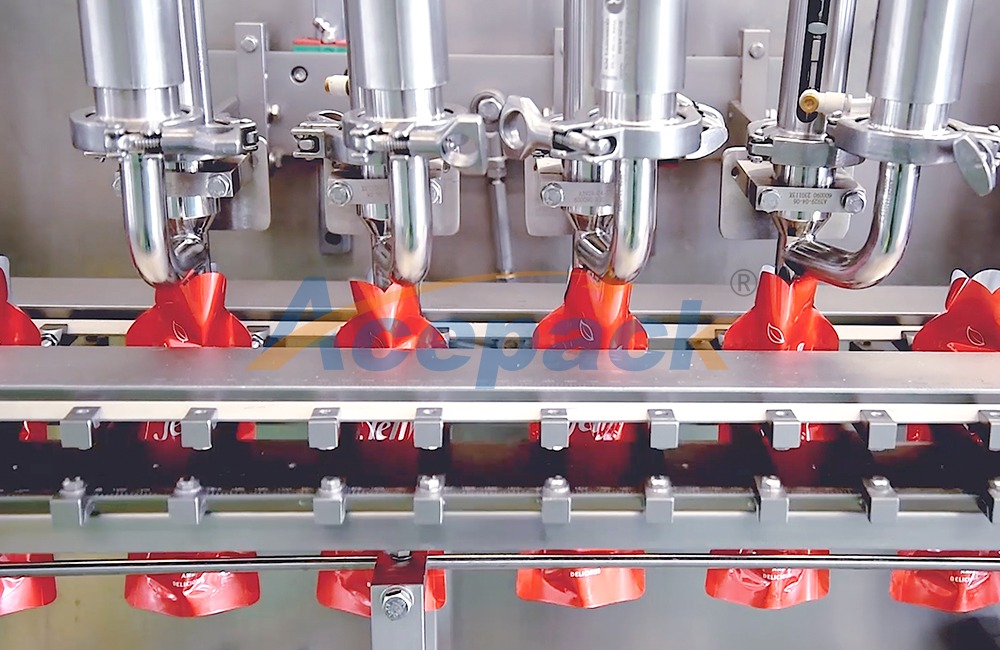

Acepack deployed its advanced DS-360QS Fully Automatic Four-Lane Roll-Fed High-Speed Shaped Pouch Packaging Machine, specifically engineered for Da Min Foods' cold brew coffee needs

Key innovations include:

Doubled Production Speed: Output surged to over 160 bags per minute – a 100% increase.

Precision Customization: Modular design with bespoke tooling enables unique pouch shapes.

Patented Acepack Technologies:

Custom Pouch Shaping: Creates distinctive, brand-defining package designs.

Independent Cooling System: Ensures superior pouch seal integrity and aesthetics.

Self-Lubricating System: Streamlines maintenance and standardizes operational procedures (SOP).

Independent Servo Dosing System: Delivers exceptional filling accuracy and stability.

Full CIP Integration: Achieves comprehensive, recirculating cleaning with zero dead zones.

Quantifiable Results & Client Endorsement:

The implementation delivered immediate, measurable improvements for Da Min Foods:

Enhanced Precision: Fill accuracy significantly improved from ±1.5% to ±1%.

Boosted Overall Efficiency: OEE (Overall Equipment Effectiveness) rose from below 90% to over 95%.

Reduced Waste: Defect rates were halved, dropping from 1% to just 0.5%.