Understanding Pharmaceutical Liquid Stick Pack Packaging Machines and Multi-Lane Sachet Packing Machines: A Q&A Guide Introduction

Jul 30, 2025

In the fast-paced world of pharmaceuticals, efficient packaging is crucial for maintaining product integrity and ensuring ease of use. Two popular solutions in this domain are pharmaceutical liquid stick pack packaging machines and multi-lane sachet packing machines. In this blog, we will explore these technologies through a Q&A format to help you understand their functionalities, benefits, and applications.

What are pharmaceutical liquid stick pack packaging machines?

Pharmaceutical liquid stick pack packaging machines are specialized equipment designed to package liquid products into stick packs. These machines create a sealed, elongated pouch that is easy to handle and dispense. The stick packs are typically made from flexible materials that provide a barrier against moisture, light, and oxygen, ensuring the stability and shelf life of the liquid contents.

What types of liquids can be packaged using these machines?

These machines are versatile and can package a wide range of liquid products, including syrups, gels, oils, and even some pharmaceutical solutions. They are particularly useful for products that require precise dosing and easy portability, such as single-dose medications, nutritional supplements, and cosmetic serums.

How do pharmaceutical liquid stick pack packaging machines work?

The process begins with the feeding of packaging material into the machine. The material is then formed into a stick shape, and the liquid is filled into the pouch. The machine uses heat sealing or cold sealing techniques to close the pack securely. Advanced models may also include features like nitrogen flushing to displace oxygen, enhancing product stability.

What are the advantages of using stick pack packaging for pharmaceuticals?

Stick pack packaging offers several advantages, including:

- Portability: The slim design makes it easy for consumers to carry and use.

- Single-dose convenience: Each stick pack contains a pre-measured dose, reducing the risk of over or under-dosing.

- Extended shelf life: The sealed environment protects the contents from external factors.

- Reduced waste: Stick packs often use less material than traditional packaging, contributing to sustainability efforts.

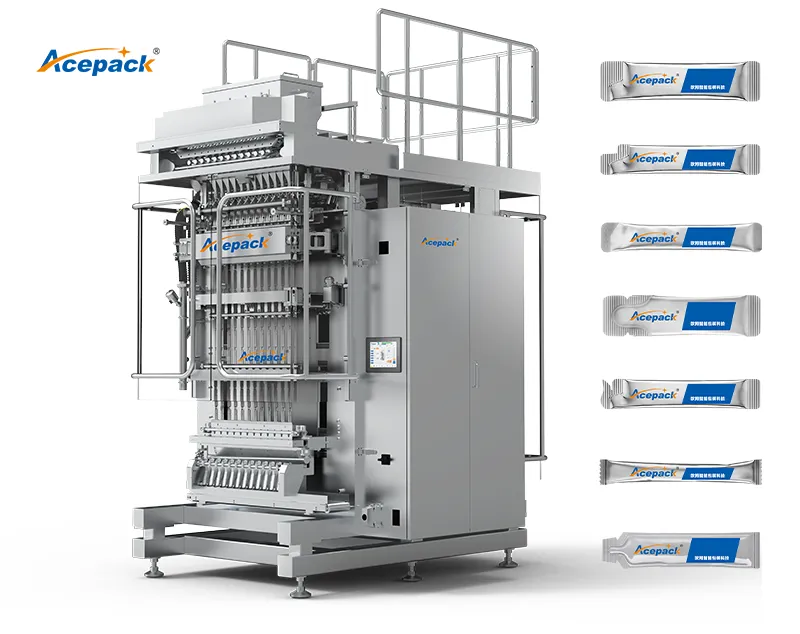

What is a multi-lane sachet packing machine?

A multi-lane sachet packing machine is a type of packaging equipment that produces multiple sachets simultaneously. These machines are designed to fill and seal pouches containing powders, granules, or liquids, making them suitable for a variety of products, including pharmaceuticals, food items, and personal care products.

How does a multi-lane sachet packing machine operate?

The operation of a multi-lane sachet packing machine involves several steps:

- Material feeding: The packaging material is fed into the machine, which can handle multiple lanes at once.

- Filling: The product is dispensed into each lane, ensuring uniformity in quantity.

- Sealing: The sachets are sealed using heat or cold sealing methods, depending on the material used.

- Cutting: The machine cuts the sachets apart, creating individual packages ready for distribution.

What are the benefits of using multi-lane sachet packing machines?

Multi-lane sachet packing machines offer numerous benefits, including:

- High efficiency: They can produce a large number of sachets in a short amount of time, making them ideal for high-volume production.

- Cost-effectiveness: By producing multiple sachets simultaneously, these machines reduce labor and operational costs.

- Versatility: They can handle various product types, including powders, granules, and liquids, making them suitable for diverse industries.

- Consistent quality: Automated processes ensure uniformity in filling and sealing, enhancing product quality.

How do pharmaceutical liquid stick pack machines and multi-lane sachet packing machines compare?

While both machines serve the purpose of packaging, they cater to different needs:

- Product Type: Stick pack machines are primarily designed for liquids, while multi-lane sachet machines can handle a broader range of products, including powders and granules.

- Packaging Format: Stick packs are elongated and slim, ideal for single doses, whereas sachets can come in various shapes and sizes.

- Production Speed: Multi-lane sachet machines typically offer higher production speeds due to their ability to produce multiple packages simultaneously.

What should companies consider when choosing between these packaging solutions?

Companies should consider several factors, including:

- Product characteristics: The nature of the product (liquid vs. powder) will dictate the choice of machine.

- Production volume: High-volume production may benefit from multi-lane sachet machines for efficiency.

- Market trends: Understanding consumer preferences for packaging formats can influence the decision.

- Budget: The initial investment and operational costs should align with the company’s financial capabilities.

Conclusion

In the pharmaceutical industry, choosing the right packaging solution is essential for product success. Pharmaceutical liquid stick pack packaging machines and multi-lane sachet packing machines each offer unique advantages tailored to specific product needs. By understanding their functionalities and benefits, companies can make informed decisions that enhance their packaging processes and ultimately improve customer satisfaction.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Feb 12, 2026

What can Shaped Doypack Packing Machine do?