Prompt response: Upon receiving your inquiry, a professional sales engineer will promptly communicate with you to understand your specific needs.

Tailored solutions: Our sales engineers not only grasp your packaging requirements but also provide suggestions based on their extensive experience with related products.

Rich case experience: Our sales engineers have dealt with various cases and possess a deep understanding of the precautions involved in packing different types of powders, granules, and liquids into various bag types.

Involvement of project engineers: For non-standard projects, our project engineers will participate in evaluating your project and offer the most reasonable and cost-effective solution.

Comprehensive technical support: Our sales engineers and project engineers are committed to providing comprehensive technical support, ensuring that you receive satisfactory packaging solutions.

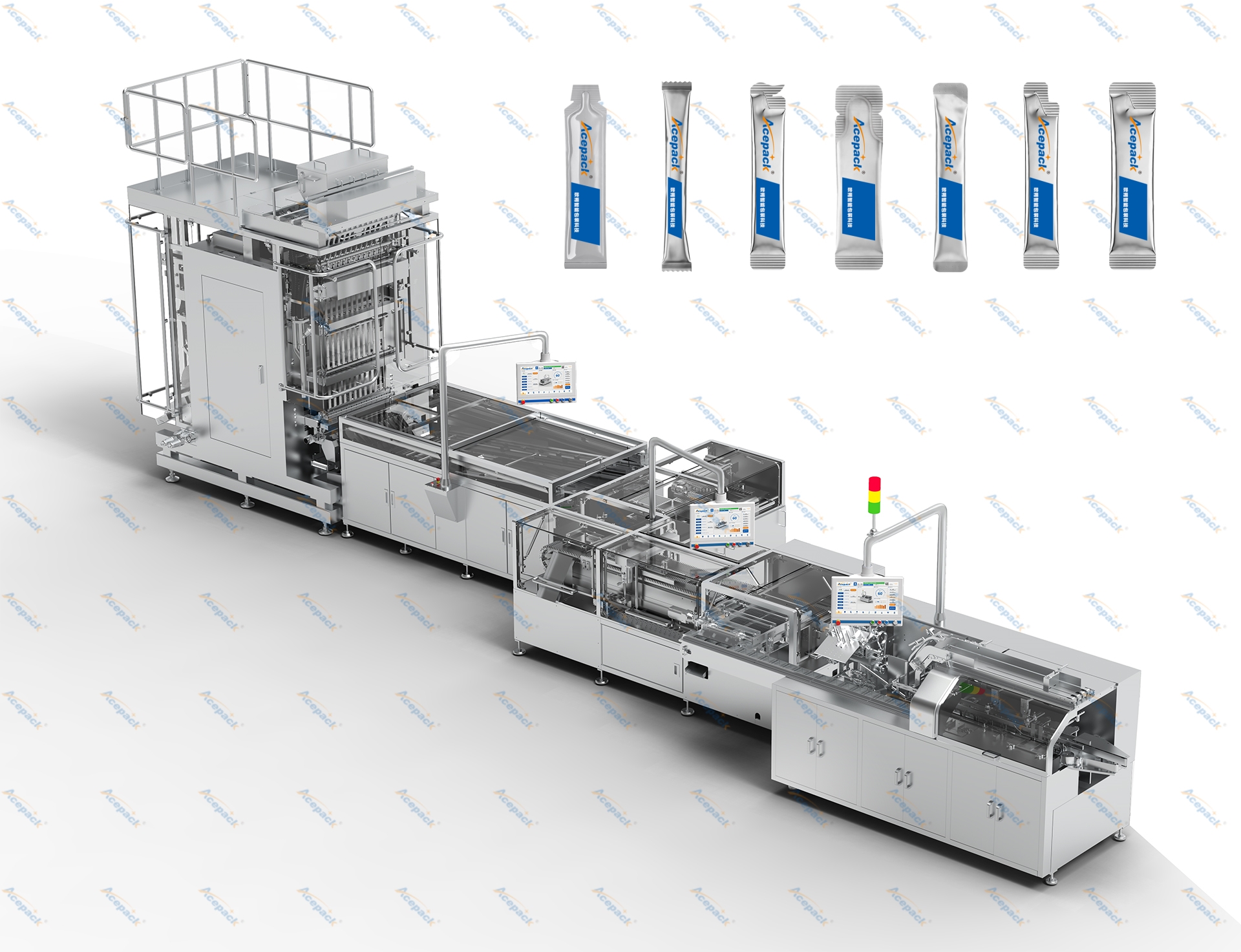

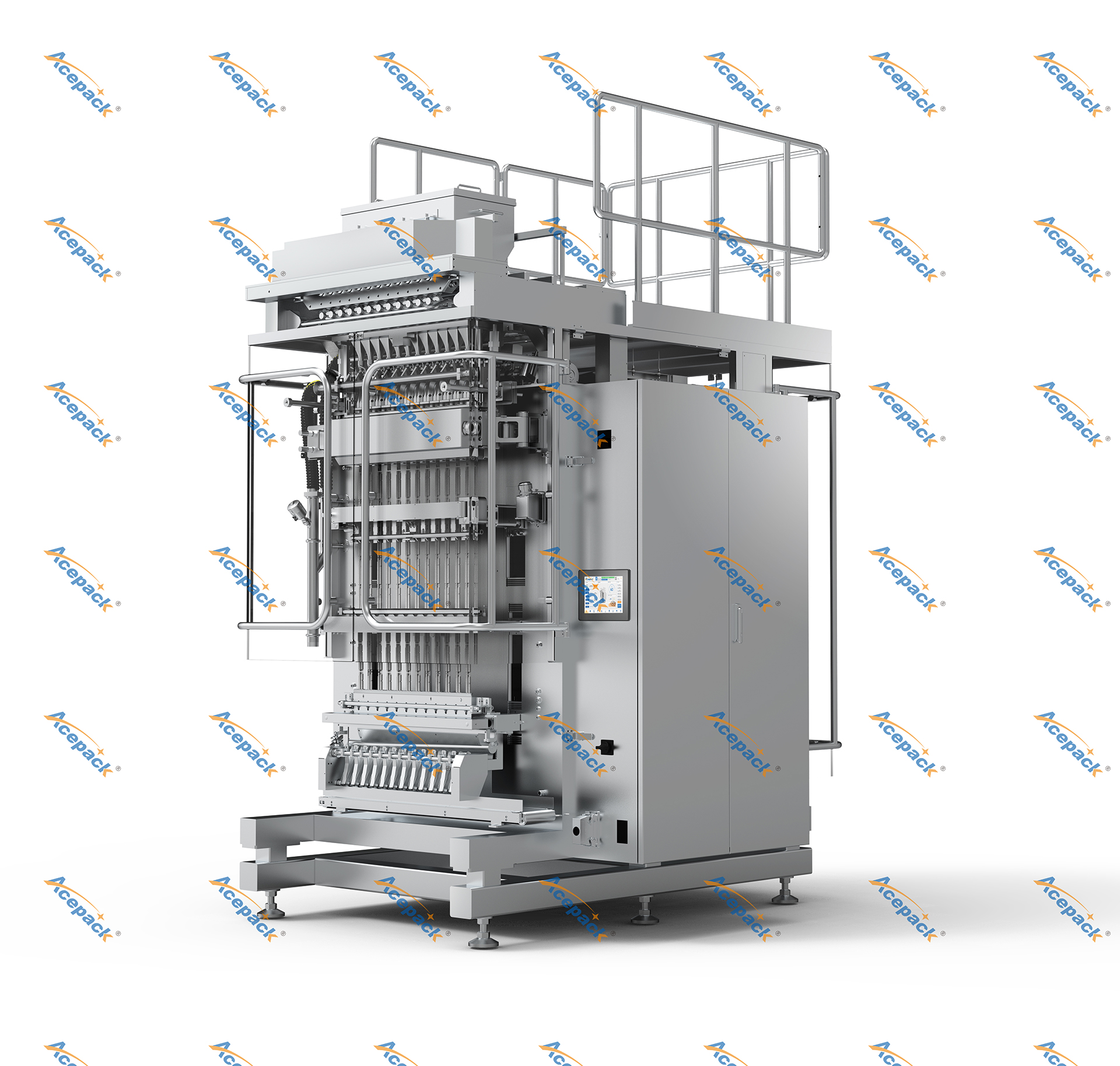

Multi-Lane Sachet Packing Machine

The Multilane stick packing machine by Acepack automates the formation, filling, and sealing of sachets and pouches for diverse product formats. Engineered for granular materials, powdered substances, and liquid formulations, this advanced stick packing machine efficiently handles single-dose packaging of free-flowing items including sweeteners, condiments (ketchup/mustard/honey), dry goods (salt/pepper/coffee), instant consumables (soups/beverages), dairy derivatives, and viscous preparations.

Featuring adjustable sizing configurations, the Multilane stick packing machine accommodates widths between 15mm-70mm and lengths spanning 60mm-180mm, enabling customized portioning for varied market requirements. Its multi-track design supports simultaneous processing of rectangular and stylized stick packs, enhancing throughput efficiency across production cycles.

Multilane Stick Packing Machine DATA SHEET:

Featuring adjustable sizing configurations, the Multilane stick packing machine accommodates widths between 15mm-70mm and lengths spanning 60mm-180mm, enabling customized portioning for varied market requirements. Its multi-track design supports simultaneous processing of rectangular and stylized stick packs, enhancing throughput efficiency across production cycles.

| Model | MS-200 | MS-500 | MS-700 | MS-900 |

| Lane number (lane) | 1-4 | 4-12 | 4-18 | 5-18 |

| Measuring method |

Ceramic pump,Long screw,Short screw,Volumetric cup,electronic granulation counter |

Ceramic pump,Long screw,Short screw,Volumetric cup,electronic granulation counter | Ceramic pump,Long screw,Short screw,Volumetric cup,electronic granulation counter | Ceramic pump,Long screw,Short screw,Volumetric cup,electronic granulation counter |

| Packaging speed | 40-80 bags/lane/minute | 40-80 bags/lane/minute | 40-80 bags/lane/minute | 40-80 bags/lane/minute |

| Filling capacity | powder:0.5-50g,granule:0.5-30g,liquid:5-50ml,pills&tablets:1-120pc | powder:0.5-50g,granule:0.5-30g,liquid:5-50ml,pills&tablets:1-120pc | powder:0.5-50g,granule:0.5-30g,liquid:5-50ml,pills&tablets:1-120pc | powder:0.5-50g,granule:0.5-30g,liquid:5-50ml,pills&tablets:1-120pc |

| Sachet size | L:60-180mm,W:15-70mm | L:60-180mm,W:15-70mm | L:60-180mm,W:15-70mm | L:60-180mm,W:15-70mm |

| Film width | Max:260mm | Max:500mm | Max:750mm | Max:980mm |

| Sealing type | Back sealing/Stick bag | Back sealing/Stick bag | Back sealing/Stick bag | Back sealing/Stick bag |

| Cutting type | Straight cutting,Zig zag cutting,Round corner cutting,Die-cut | Straight cutting,Zig zag cutting,Round corner cutting,Die-cut | Straight cutting,Zig zag cutting,Round corner cutting,Die-cut | Straight cutting,Zig zag cutting,Round corner cutting,Die-cut |

| Air&Power | 0.8Mpa/0.8-1.2m3/min;3.5-20kw | 0.8Mpa/0.8-1.2m3/min;3.5-20kw | 0.8Mpa/0.8-1.2m3/min;3.5-20kw | 0.8Mpa/0.8-1.2m3/min;3.5-20kw |

| Machine dimension&width | 1750*1100mm;1300kg | 2400*1550mm;3000kg | 2400*1800mm;about 3200kg | 2400*2050;about 3500kg |

Stick Packing Machine Application:

This high-performance stick packing machine delivers operational flexibility for pharmaceutical applications, food manufacturing, agrochemical processing, and industrial chemical sectors. It is an excellent solution for pharmaceutical packaging.With its user-centric interface and precision engineering, the Multilane stick packing machine ensures reliable packaging quality while maintaining adaptability for evolving production demands. The equipment's robust construction and multi-industry compatibility solidify its position as a premier solution for modern automated packaging workflows.

Variety Of Packaging Style For You To Choose

.png)

Feature of Multilane Stick Packing Machine:

1.High automation,the complete all the process automatically together from the dosing,vertical sealing,horizontal sealing,filling,date printing,cutting.

2.It can achieve various customized metering methods

3.It can meet functions such as audit trails, electronic signatures, and data statistics

4.Equipped with an 18.5-inch large industrial control screen and a newly designed human-machine interface

5.Uses a full servo control system to enhance OEE

6.Complies with EHS management reguirements

7.Stable speed can reach 70-80 cuts per minute

8.Equipped with an automatic nitrogen flling function,with residual oxygen controlled within 2%