Prompt response: Upon receiving your inquiry, a professional sales engineer will promptly communicate with you to understand your specific needs.

Tailored solutions: Our sales engineers not only grasp your packaging requirements but also provide suggestions based on their extensive experience with related products.

Rich case experience: Our sales engineers have dealt with various cases and possess a deep understanding of the precautions involved in packing different types of powders, granules, and liquids into various bag types.

Involvement of project engineers: For non-standard projects, our project engineers will participate in evaluating your project and offer the most reasonable and cost-effective solution.

Comprehensive technical support: Our sales engineers and project engineers are committed to providing comprehensive technical support, ensuring that you receive satisfactory packaging solutions.

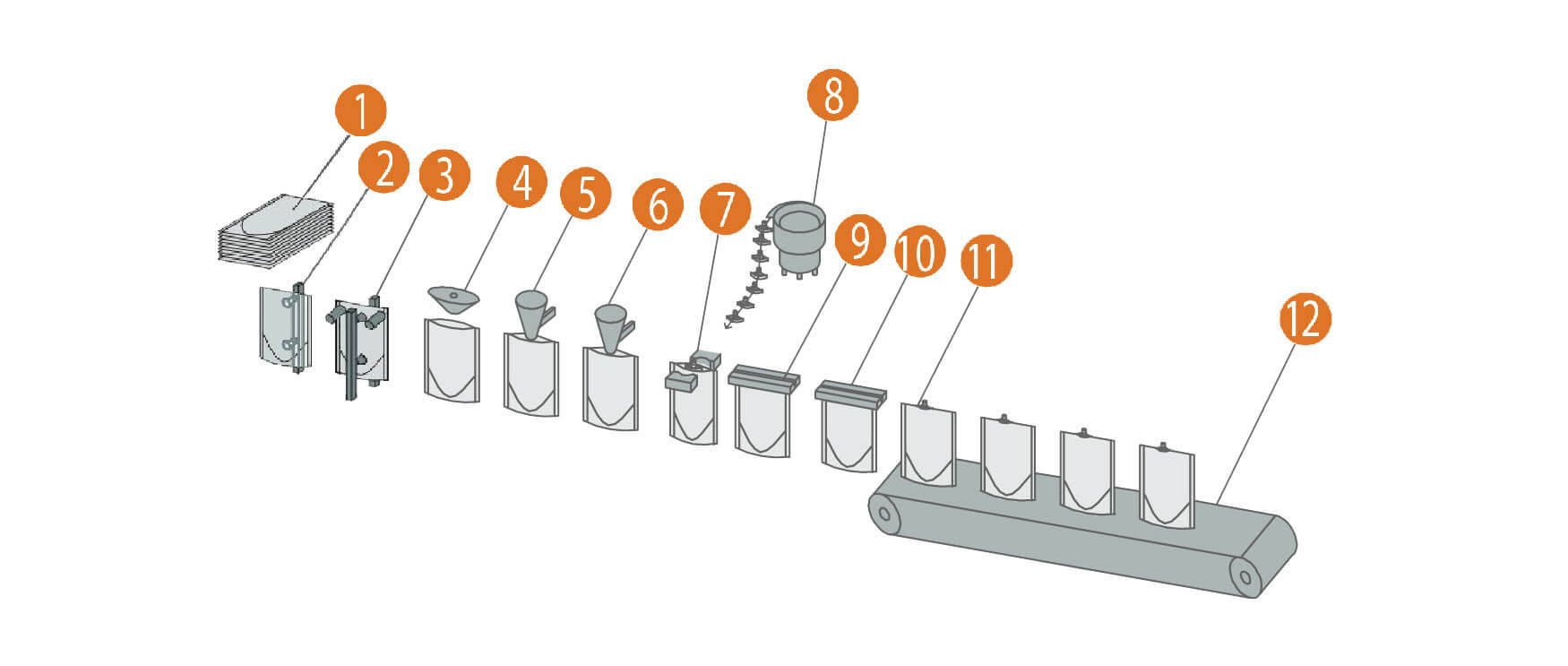

Top Spout pouch packing machine

Top spout pouch packing machine is suitable for filling packing different liquid, paste and cream products such as water, oil, milk, juice, ketchup, tomato sauce, peanut butter, honey, mayonnaise, liquid detergent, shampoo, body washing and other non free-flowing liquid when equipped with different filling machines like Piston Pump Filling, Peristaltic Pump Filling, Haibar Pump Filling. With the suitable filling solution to meet the filling accuracy and packing speed requirements and avoid the liquid material bubble, forming, dripping, and splashing.

Technical Parameter

|

model |

SG-180C |

|

Pouch Size |

60mmX80mm(Min.) |

|

Filling Capacity |

1000mL |

|

Packaging Speed |

30-60ppm |

|

Power |

2.6kw |

|

Air Consumption |

250NL/min |

|

Machine Dimensions |

2190mm(L) |

|

Weight |

800kg |

|

Function |

Flat Pouch, |

Finished Bag Photo