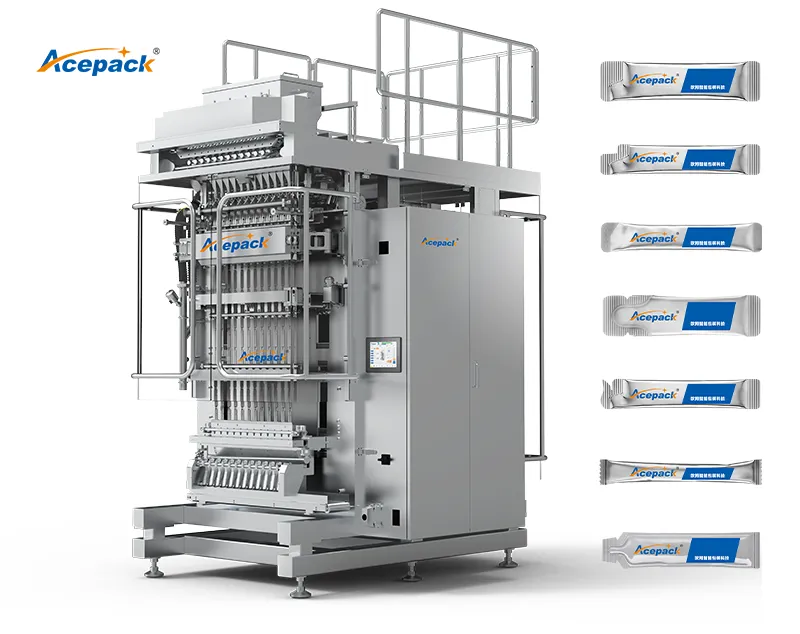

How to use multi-lane stick bag packaging machine in the pharmaceutical packaging industry

Aug 13, 2025

Using a multi-lane stick bag packaging machine in the pharmaceutical packaging industry involves several steps to ensure efficient and compliant packaging of pharmaceutical products. Here’s a guide on how to effectively use this type of machine:

Steps to Use a Multi-Lane Stick Bag Packaging Machine:

-

Preparation and Setup:

- Read the Manual: Familiarize yourself with the machine’s operation manual for specific instructions and safety guidelines.

- Clean the Machine: Ensure that the machine is clean and free from any previous product residues to avoid contamination.

- Set Up the Work Area: Organize the workspace to have all necessary materials (powders, films, etc.) within reach.

-

Material Selection:

- Choose the Right Film: Select appropriate packaging film that meets pharmaceutical standards (e.g., moisture barrier, tamper-evident features).

- Prepare the Product: Ensure that the pharmaceutical powder or granules are ready for packaging, adhering to quality control standards.

-

Machine Configuration:

- Adjust Settings: Set the machine parameters according to the product specifications, including bag length, fill volume, and sealing temperature.

- Lane Configuration: Configure the number of lanes based on production requirements. Multi-lane machines can operate multiple bags simultaneously, increasing throughput.

-

Filling Process:

- Feed the Product: Load the pharmaceutical powder into the hopper or feeding system of the machine.

- Start the Machine: Initiate the filling process. The machine will dispense the correct amount of product into each lane.

-

Sealing and Cutting:

- Monitor Sealing: Ensure that the sealing mechanism is functioning correctly to create airtight and tamper-proof bags.

- Cutting Mechanism: The machine will automatically cut the bags to the desired length after sealing.

-

Quality Control:

- Inspect Bags: Regularly check the filled bags for proper sealing, fill volume, and any defects.

- Conduct Weight Checks: Perform weight checks to ensure that the correct amount of product is being dispensed.

-

Packaging and Labeling:

- Collect Finished Bags: Gather the finished stick bags for further processing.

- Labeling: Ensure that each bag is labeled according to regulatory requirements, including product information, batch numbers, and expiration dates.

-

Maintenance:

- Regular Cleaning: Clean the machine after each production run to prevent cross-contamination.

- Routine Maintenance: Follow the manufacturer’s guidelines for routine maintenance to ensure optimal performance and longevity of the machine.

Compliance and Safety:

- Regulatory Compliance: Ensure that all packaging processes comply with pharmaceutical regulations (e.g., FDA, GMP) to maintain product safety and efficacy.

- Operator Training: Train operators on the machine’s operation, safety protocols, and emergency procedures.

By following these steps, you can effectively use a multi-lane stick bag packaging machine in the pharmaceutical packaging industry, ensuring efficient production while maintaining high standards of quality and compliance.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Feb 12, 2026

What can Shaped Doypack Packing Machine do?