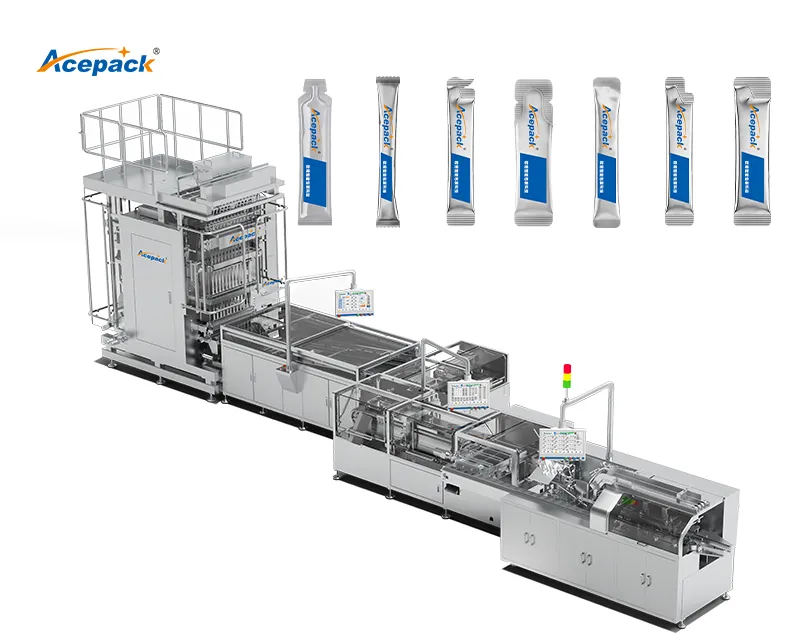

Revolutionizing Liquid Pharma Packaging with Multi-Lane VFFS Stick-Pack Machines

Aug 11, 2025

What is a Multi-Lane VFFS Stick-Pack Machine, and why is it critical for liquid pharmaceuticals?

A multi-lane Vertical Form-Fill-Seal (VFFS) machine automates the production of stick-pack pouches from a roll of film. For liquid pharmaceuticals (e.g., vaccines, oral suspensions), it enables:

High-Volume Output: 4–16 lanes run simultaneously, boosting output by 300% vs. single-lane units.

Precision Dosing: Micro-dosing pumps fill volumes from 0.5ml to 30ml with ±1% accuracy.

Aseptic Integrity: ISO Class 5 cleanroom compatibility and sterile film options prevent contamination.

How does this technology ensure product safety and compliance?

Pharma-grade VFFS machines integrate:

cGMP/ISO Compliance: Validatable per FDA 21 CFR Part 11, with audit trails and electronic records.

Leak Detection: In-line vision systems and pressure decay tests detect defective seals.

Material Compatibility: FDA-approved films (e.g., PET/Alu/PE) block oxygen, light, and moisture.

What operational efficiencies do multi-lane systems offer?

Key advantages include:

Speed: Up to 800 packs/min across 12 lanes (e.g., 100ml pediatric syrups).

Flexibility: Quick-change tooling adjusts pouch sizes (10–200mm width) in under 15 minutes.

Waste Reduction: Servo-driven film control cuts material waste by 20%.

Can these machines handle sensitive biologics or viscous fluids?

Yes. Advanced models feature:

Cold Filling: Temperature-controlled hoppers (2–8°C) for heat-sensitive APIs.

Viscosity Adaptability: Piston fillers manage fluids from 1 cP (water-like) to 50,000 cP (creams).

What about cleaning and changeover?

Design innovations include:

CIP/SIP Systems: Clean-in-Place/Sterilize-in-Place reduces downtime.

Modular Contact Parts: Washable components meet FDA sanitation standards.

How do multi-lane VFFS machines support sustainability?

They reduce environmental impact through:

Less Material: Stick-packs use 70% less plastic vs. bottles.

Energy Efficiency: Regenerative drives cut power use by 25%.

Industry Case: A European CDMO increased vaccine packaging output by 400% using a 16-lane VFFS system, with zero media-fill test failures over 12 months.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Feb 12, 2026

What can Shaped Doypack Packing Machine do?