What Are the Key Benefits of Using Food Supplement Powder Stick Pack Packaging Machines?

Jul 02, 2025

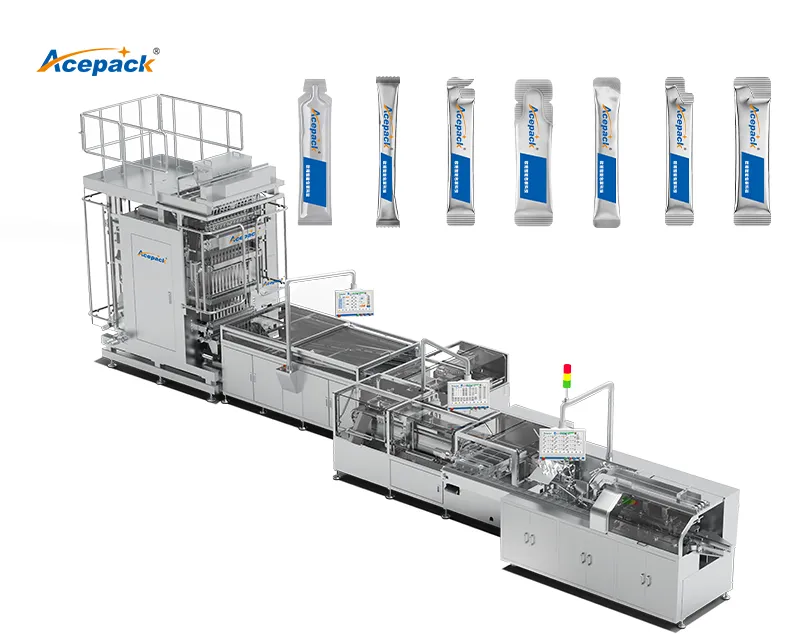

In the ever-evolving landscape of the food supplement industry, the demand for efficient, reliable, and innovative packaging solutions has never been greater. Among the various packaging options available, food supplement powder stick pack packaging machines have emerged as a game-changer. These machines not only streamline the packaging process but also enhance product quality and consumer satisfaction. In this article, we will explore the key benefits of using food supplement powder stick pack packaging machines, highlighting their advanced features and capabilities.

1. Customized Metering Methods

One of the standout features of food supplement powder stick pack packaging machines is their ability to achieve various customized metering methods. This flexibility allows manufacturers to tailor the packaging process to meet specific product requirements, ensuring that each stick pack contains the precise amount of powder needed. Whether it’s a single-serving or a multi-serving pack, these machines can be adjusted to accommodate different product formulations, enhancing accuracy and reducing waste.

2. Enhanced Compliance and Traceability

In an industry where regulatory compliance is paramount, food supplement powder stick pack packaging machines offer essential functions such as audit trails, electronic signatures, and data statistics. These features not only help manufacturers adhere to industry regulations but also provide a transparent record of the packaging process. This level of traceability is crucial for quality control and can significantly reduce the risk of product recalls, ensuring that consumers receive safe and reliable products.

3. User-Friendly Interface

The design of food supplement powder stick pack packaging machines incorporates an 18.5-inch large industrial control screen and a newly designed human-machine interface. This user-friendly interface simplifies the operation of the machine, allowing operators to easily monitor and control the packaging process. With intuitive navigation and clear visual displays, training new staff becomes more efficient, reducing downtime and increasing productivity.

4. Full Servo Control System

The implementation of a full servo control system in food supplement powder stick pack packaging machines enhances Overall Equipment Effectiveness (OEE). This advanced technology ensures precise control over the packaging process, resulting in improved speed, accuracy, and consistency. By minimizing mechanical wear and tear, the servo system also contributes to lower maintenance costs and longer machine lifespan, making it a cost-effective solution for manufacturers.

5. High-Speed Operation

Speed is a critical factor in the packaging industry, and food supplement powder stick pack packaging machines excel in this area. With a stable speed that can reach 70-80 cuts per minute, these machines significantly increase production capacity. This high-speed operation allows manufacturers to meet growing consumer demand without compromising on quality, ultimately leading to higher profitability.

6. Automatic Nitrogen Filling Function

To preserve the freshness and quality of food supplements, many manufacturers are turning to nitrogen flushing as a packaging solution. Food supplement powder stick pack packaging machines are equipped with an automatic nitrogen filling function, which controls residual oxygen levels within 2%. This feature is essential for extending the shelf life of products, preventing oxidation, and maintaining the potency of active ingredients. By ensuring that products are packaged in an oxygen-free environment, manufacturers can deliver superior quality to consumers.

7. Compliance with EHS Management Requirements

Environmental, Health, and Safety (EHS) management is a critical consideration for modern manufacturers. Food supplement powder stick pack packaging machines are designed to comply with EHS management requirements, ensuring that the packaging process is safe for both operators and the environment. By adhering to these standards, manufacturers can mitigate risks and promote a culture of safety within their operations.

8. Customized End-to-End Solutions

Every manufacturer has unique needs, and food supplement powder stick pack packaging machines provide customized end-to-end solutions. From initial product design to final packaging, these machines can be tailored to fit specific production workflows. This level of customization not only enhances efficiency but also allows manufacturers to differentiate their products in a competitive market.

Conclusion

The benefits of using food supplement powder stick pack packaging machines are manifold. From customized metering methods and enhanced compliance to high-speed operation and automatic nitrogen filling, these machines are designed to meet the demands of the modern food supplement industry. By investing in advanced packaging technology, manufacturers can improve product quality, increase efficiency, and ultimately drive business growth. As the industry continues to evolve, the role of innovative packaging solutions will be crucial in meeting consumer expectations and maintaining a competitive edge.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Feb 12, 2026

What can Shaped Doypack Packing Machine do?