How Do Pharmaceutical Stick Pack Packaging Machines Revolutionize the Industry?

Jul 01, 2025

In the fast-paced world of pharmaceuticals, efficiency, precision, and compliance are paramount. As the industry continues to evolve, so too do the technologies that support it. One of the most significant advancements in recent years is the development of pharmaceutical stick pack packaging machines. These machines are not just a trend; they are revolutionizing the way pharmaceutical products are packaged, ensuring that they meet the highest standards of quality and safety.

The Rise of Stick Pack Packaging

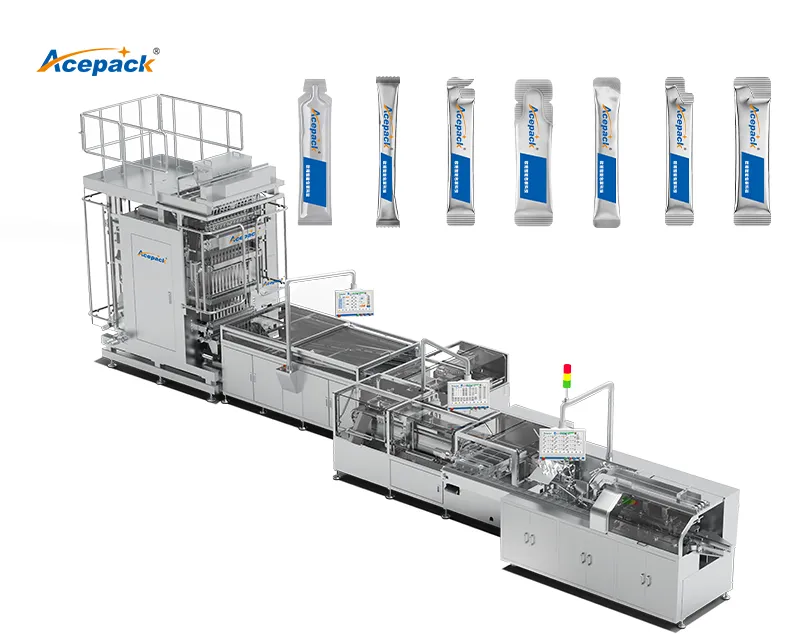

Stick pack packaging has gained immense popularity in the pharmaceutical sector due to its convenience and efficiency. Unlike traditional packaging methods, stick packs are lightweight, easy to transport, and provide a single-dose solution that enhances user experience. This format is particularly beneficial for liquid medications, powders, and granules, allowing for precise dosing and minimizing waste.

Customized Metering Methods

One of the standout features of modern pharmaceutical stick pack packaging machines is their ability to achieve various customized metering methods. This flexibility allows manufacturers to tailor the packaging process to the specific needs of their products. Whether it’s a viscous liquid or a fine powder, these machines can be adjusted to ensure accurate filling, which is crucial for maintaining dosage integrity and compliance with regulatory standards.

Enhanced Compliance Features

In an industry where compliance is non-negotiable, pharmaceutical stick pack packaging machines come equipped with advanced features that meet stringent requirements. Functions such as audit trails, electronic signatures, and data statistics are integrated into the packaging process, ensuring that every step is documented and traceable. This level of transparency not only enhances accountability but also aids in regulatory inspections, making it easier for companies to demonstrate compliance with industry standards.

User-Friendly Interface

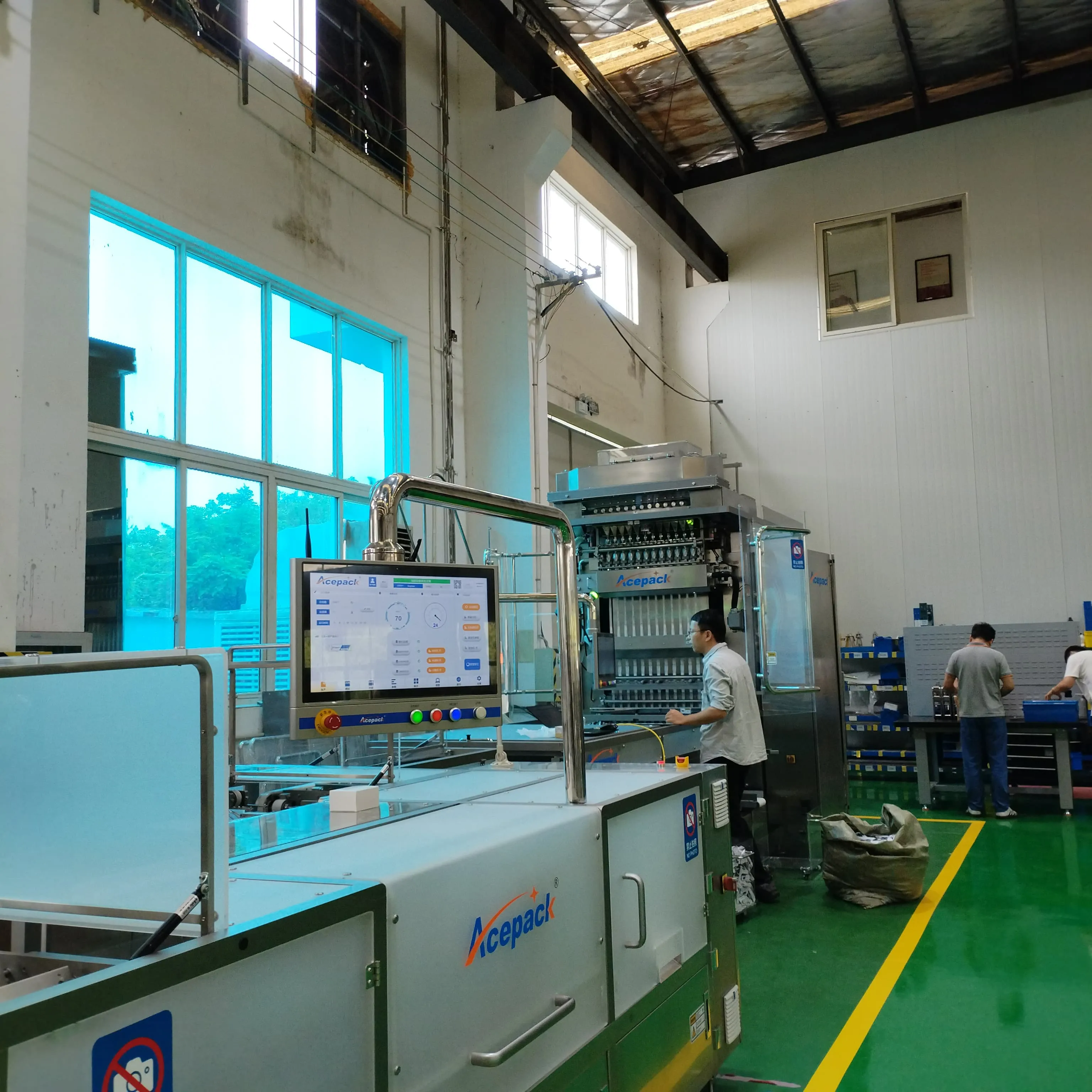

The user experience is a critical aspect of any machinery, and pharmaceutical stick pack packaging machines are no exception. With an 18.5-inch large industrial control screen and a newly designed human-machine interface, operators can easily monitor and control the packaging process. This intuitive interface reduces the learning curve for new operators and minimizes the risk of errors, ultimately leading to increased productivity and efficiency on the production line.

Full Servo Control System

The implementation of a full servo control system in these machines significantly enhances Overall Equipment Effectiveness (OEE). This technology allows for precise control over the packaging process, resulting in higher speeds and improved accuracy. With stable speeds reaching 70-80 cuts per minute, manufacturers can increase their output without compromising on quality. The ability to maintain such high speeds while ensuring precision is a game-changer for the pharmaceutical industry, where time and accuracy are of the essence.

EHS Management Compliance

Environmental, Health, and Safety (EHS) management requirements are critical in the pharmaceutical industry. Modern stick pack packaging machines are designed to comply with these regulations, ensuring that the packaging process is safe for both operators and the environment. By integrating EHS management features, manufacturers can mitigate risks and promote a culture of safety within their operations.

Nitrogen Filling Function

Another innovative feature of pharmaceutical stick pack packaging machines is the automatic nitrogen filling function. This technology is essential for preserving the integrity of sensitive pharmaceutical products. By controlling residual oxygen levels to within 2%, manufacturers can significantly extend the shelf life of their products and maintain their efficacy. This is particularly important for products that are sensitive to oxidation, as it helps to ensure that patients receive medications that are both safe and effective.

Customized End-to-End Solutions

The versatility of pharmaceutical stick pack packaging machines allows manufacturers to provide customized end-to-end solutions. From the initial design phase to the final packaging, these machines can be tailored to meet the unique needs of each product. This customization not only enhances efficiency but also allows for greater innovation in product development. As the pharmaceutical industry continues to grow and diversify, the ability to adapt packaging solutions to meet specific requirements will be crucial for success.

Conclusion

Pharmaceutical stick pack packaging machines are more than just a technological advancement; they represent a significant shift in how the industry approaches packaging. With their ability to achieve customized metering methods, enhance compliance, and improve user experience, these machines are setting new standards for efficiency and quality. As the pharmaceutical landscape continues to evolve, the adoption of these innovative packaging solutions will be essential for manufacturers looking to stay competitive and meet the ever-increasing demands of the market. The future of pharmaceutical packaging is here, and it is revolutionized by stick pack technology.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Feb 12, 2026

What can Shaped Doypack Packing Machine do?