Why Should You Invest in Probiotics Stick Pack Packaging Machines for Efficient Product Delivery?

Jun 30, 2025

In the ever-evolving landscape of the food and beverage industry, the demand for probiotics has surged, driven by a growing awareness of gut health and overall wellness. As a result, manufacturers are seeking innovative solutions to package these products efficiently and effectively. One such solution is the investment in probiotics stick pack packaging machines. These machines not only streamline the packaging process but also enhance product delivery, ensuring that consumers receive high-quality probiotics in a convenient format.

The Rise of Probiotics

Probiotics, often referred to as “good bacteria,” are live microorganisms that provide health benefits when consumed in adequate amounts. They are commonly found in fermented foods and dietary supplements. The increasing popularity of probiotics has led to a surge in demand for convenient packaging options, such as stick packs. These single-serving packets are not only easy to use but also help maintain the integrity of the product, ensuring that consumers receive the full benefits of the probiotics.

The Importance of Efficient Packaging

Efficient packaging is crucial for any product, but it is especially important for probiotics. These products are sensitive to environmental factors such as moisture and oxygen, which can compromise their efficacy. Therefore, investing in advanced packaging technology is essential for manufacturers looking to deliver high-quality probiotics to their customers. Probiotics stick pack packaging machines offer a range of features that enhance the packaging process, ensuring that products are delivered efficiently and effectively.

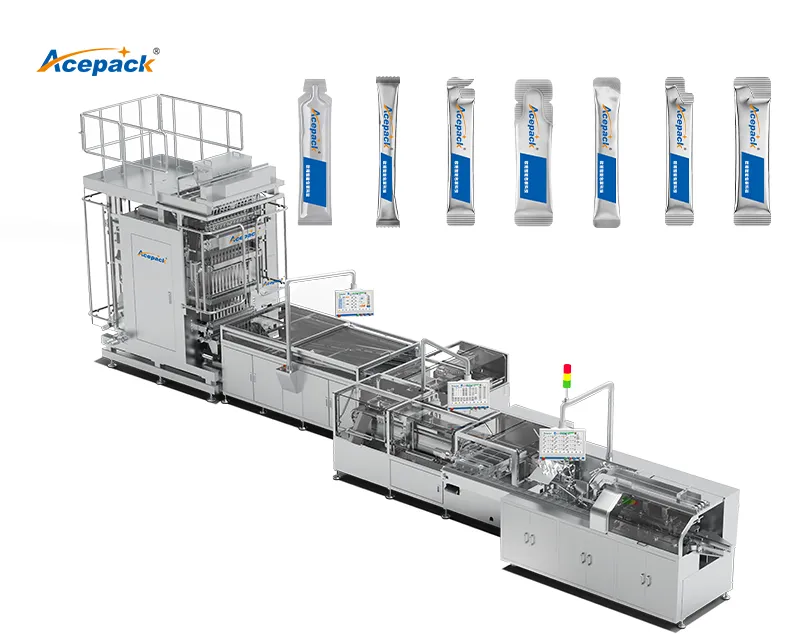

Key Features of Probiotics Stick Pack Packaging Machines

-

Customized Metering Methods: One of the standout features of probiotics stick pack packaging machines is their ability to achieve various customized metering methods. This flexibility allows manufacturers to package different types of probiotics, whether in powder or liquid form, ensuring that each product is accurately dosed for optimal effectiveness.

-

Audit Trails and Electronic Signatures: In an industry where compliance and traceability are paramount, these machines meet functions such as audit trails and electronic signatures. This capability not only enhances accountability but also ensures that manufacturers can easily track their products throughout the packaging process.

-

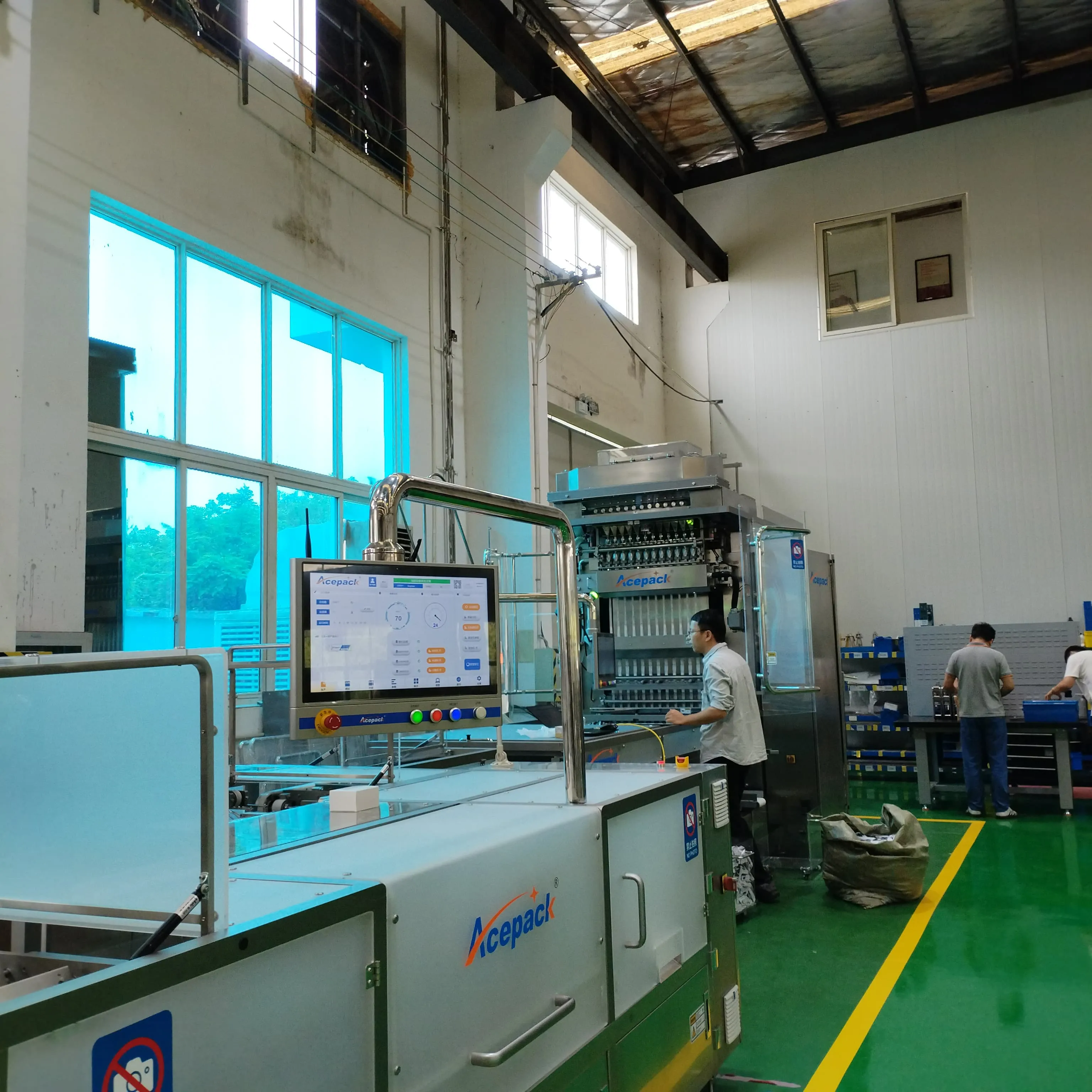

User-Friendly Interface: The 18.5-inch large industrial control screen and newly designed human-machine interface make operating the packaging machine intuitive and straightforward. This user-friendly design minimizes the learning curve for operators, allowing for quicker training and increased productivity.

-

Full Servo Control System: The full servo control system enhances Overall Equipment Effectiveness (OEE) by providing precise control over the packaging process. This technology reduces downtime and increases efficiency, allowing manufacturers to meet growing consumer demand without sacrificing quality.

-

EHS Management Compliance: With Environmental, Health, and Safety (EHS) management requirements becoming increasingly stringent, these machines are designed to comply with industry standards. This commitment to safety not only protects workers but also ensures that the packaging process is environmentally friendly.

-

High-Speed Production: The speed of these machines can reach an impressive 70-80 cuts per minute, significantly increasing production capacity. This high-speed capability is essential for manufacturers looking to scale their operations and meet the demands of a competitive market.

-

Automatic Nitrogen Filling Function: To preserve the quality of probiotics, the machines come equipped with an automatic nitrogen filling function. This feature controls residual oxygen levels within 2%, ensuring that the probiotics remain viable and effective throughout their shelf life.

-

Customized End-to-End Solutions: Finally, probiotics stick pack packaging machines provide customized end-to-end solutions tailored to the specific needs of manufacturers. This flexibility allows businesses to adapt their packaging processes to meet changing market demands and consumer preferences.

The Bottom Line: Investing in the Future

Investing in probiotics stick pack packaging machines is not just a smart business decision; it is a strategic move that positions manufacturers for success in a rapidly growing market. With the ability to customize metering methods, ensure compliance with industry standards, and enhance production efficiency, these machines are essential for delivering high-quality probiotics to consumers.

As the demand for probiotics continues to rise, manufacturers must prioritize efficient packaging solutions that protect product integrity and enhance consumer convenience. By investing in advanced packaging technology, businesses can not only improve their operational efficiency but also build a reputation for quality and reliability in the eyes of consumers.

The benefits of probiotics stick pack packaging machines are clear. They offer a comprehensive solution for manufacturers looking to streamline their packaging processes while ensuring that their products meet the highest standards of quality. As the probiotics market continues to expand, now is the time to invest in the technology that will drive your business forward.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Feb 12, 2026

What can Shaped Doypack Packing Machine do?