Prompt response: Upon receiving your inquiry, a professional sales engineer will promptly communicate with you to understand your specific needs.

Tailored solutions: Our sales engineers not only grasp your packaging requirements but also provide suggestions based on their extensive experience with related products.

Rich case experience: Our sales engineers have dealt with various cases and possess a deep understanding of the precautions involved in packing different types of powders, granules, and liquids into various bag types.

Involvement of project engineers: For non-standard projects, our project engineers will participate in evaluating your project and offer the most reasonable and cost-effective solution.

Comprehensive technical support: Our sales engineers and project engineers are committed to providing comprehensive technical support, ensuring that you receive satisfactory packaging solutions.

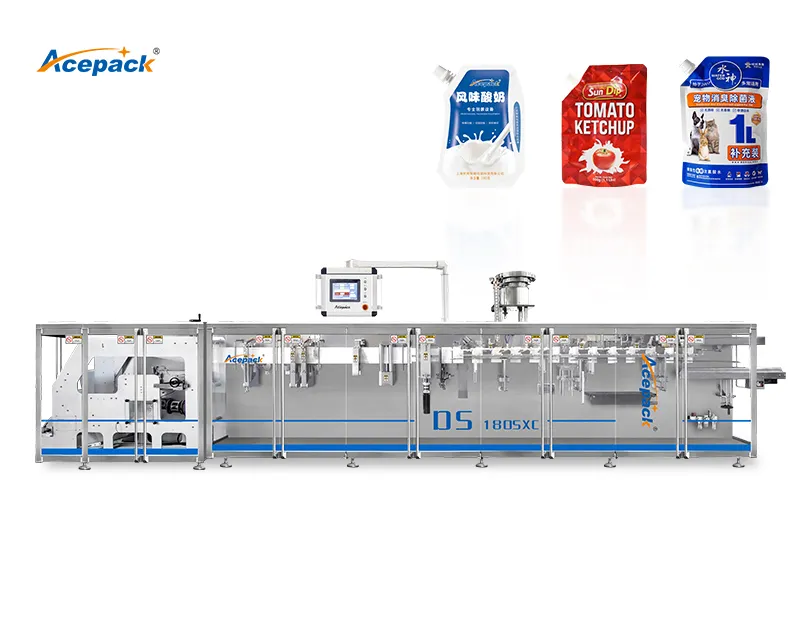

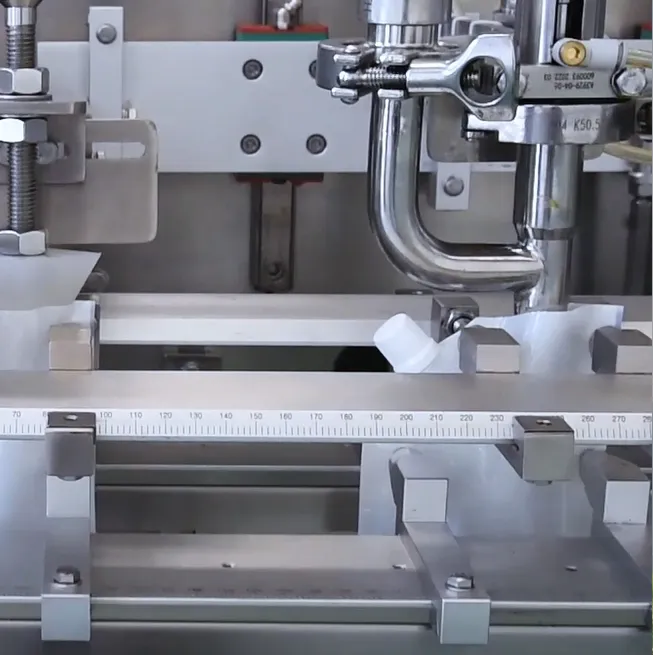

HFFS Corner Spout Pouch Filling Machine

Acepack Horizontal Form Fill Seal Spout Pouch Filling Packing Machine is a specialized type of pouch filling machine designed specifically for filling conner spouted pouches.

It's a key piece of equipment in modern flexible packaging, enabling easy filling for liquid and viscous products, as well as powder, and granule products.

Typical Applications of Horizontal Form Fill Seal Spout Pouch Filling Packing Machine:

Liquids: sauces (soy, ketchup), syrup, liquid dairy, beverage concentrates.

Viscous Products: Yogurt, pudding, baby food, condiments (mayonnaise, mustard), liquid soap, shampoos, lubricants.

Powders & Granules: Detergents, nutritional powders, drink mixes (where a pouring/spout function is desired).

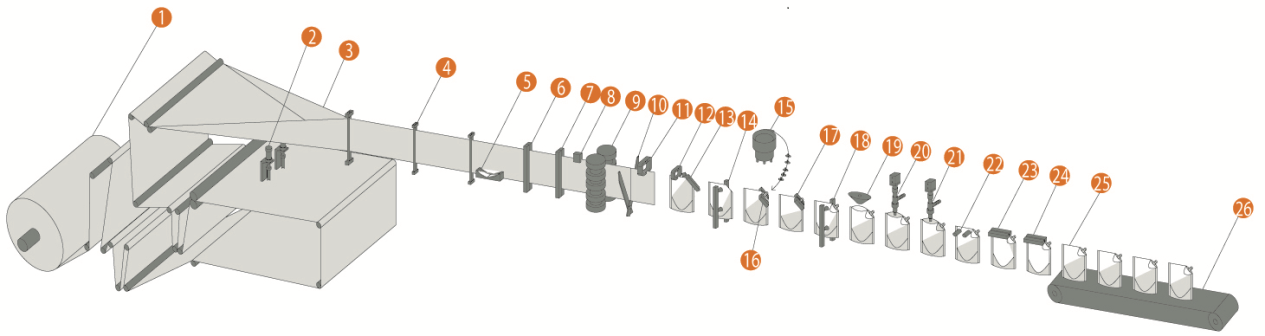

Filling Process:

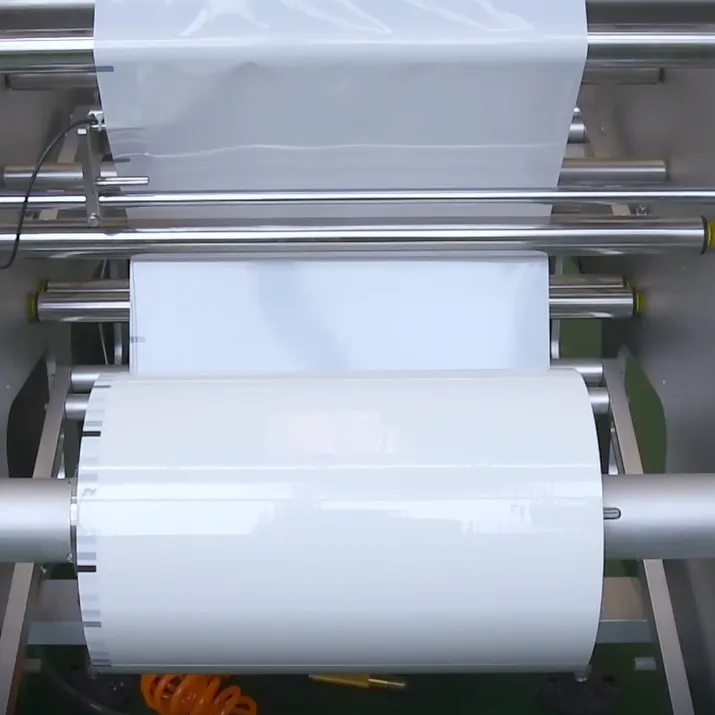

| 1.Film Unwind | 2.Bottom Hole Pouching | 3.Bag Forming | 4.Film Guide | 5.Bottom Seal |

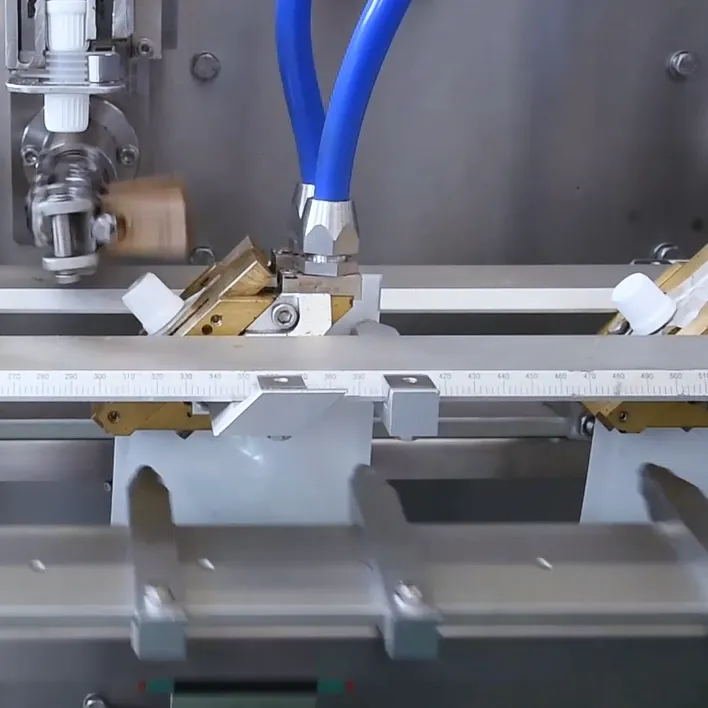

| 6.Vertical Seal I | 7.Vertical Seal II | 8.Photocell | 9.Servo Advance | 10.Cutting |

| 11+12.Pouch Catching | 13.Slant Opening Cutting | 14.First Pouch Opening | 15.Vibrator | 16.Spout Inserting |

| 17.Spout Seal | 18.Second Pouch Opening | 9.Air Flushing | 20.Filling I | 21.Filling II |

| 22.Pouch Stretching | 23.Top Seal I | 24.Top Seal II | 25.Finished Product | 26.Outlet |

Technical Parameter

|

Modle |

DS-180SXC |

DS-240SXC |

DS-280DSXC |

|

Pouch Size |

110*170mm(Min) |

110*170mm(Min) |

110*170mm(Min) |

|

Filling capacity |

1200ml |

2500ml |

600ml |

|

Packing capacity |

30-50ppm |

30-50ppm |

80-100ppm |

|

Powder |

11KW |

11.4KW |

15.8kw |

|

Air consumption |

400NL/min |

400NL/min |

800NL/min |

|

Machine Dimensions |

7450mm(L) |

7300mm(L) |

9900mm(L) |

|

Weight |

4500kg |

4500kg |

5850kg |

|

Function |

Doypack,Shape, |

Doypack, |

Doypack, |

Finished Bag Photo